- Joined

- Jun 19, 2010

- Messages

- 1,487

- Points

- 63

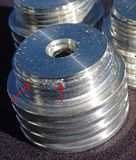

Howdy there....Any word on the Un-Anodized grooves?

Looking Very forward to my builds.

Looking Very forward to my builds.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

sorry I haven't posted in a while guys, it isn't for lack of trying. this phone has the worst browser and if you thought lpf was bad on a computer with all the ads and such you should see it on my phone. took me an hour just to get in this thread.

I have not even started polishing as the weather just hasn't permitted it. I will get to some today as the sun seems to be shining thus far.

my responses will be slow until I get into an apartment and get internet back on my pc.

Well folks I started polishing today and removed the heads to clean them individually and the threaads are messed up and won't tthread onto the barrels easily. I need to contact pontiac and find the thread size so that I can chase the threAds. Hopefully trthis fixes the issue. Will keep yua all updated.

If the threads are tight now, just wait until you anodize them...

Unless you are not anodizing the threads.

What exactly is not fitting right? I sent them all assembled and they all fit fine for me.

The threads are a non standard size, I'm not sure you'll be able to find a tap. I can't remember exactly but I think they are M20x1.25