- Joined

- Jul 10, 2015

- Messages

- 13,093

- Points

- 113

If you want to use a linear like that configure it as a current regulator not a voltage regulator, also you need DC not AC

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Seconded: you need more heat. Soldering directly to the batteries is a bit tricky. You want to minimize the amount of heat, especially when soldering to the positive terminal. Using a higher power iron or gun will allow you to make good solder joints in just a few seconds rather than slowly 'cooking' the battery trying to melt the solder with a lower power iron. The risk with the high power gun is there's no temperature control so you must work quickly to avoid melting the seal around the positive terminal.Very nice but let me offer a suggestion, when soldering thicker wire to batteries use a 100-150W soldering gun or large soldering iron so you can liquefy all the solder at once and make a good uniform connection, because using too small of a soldering iron the larger material sucks the heat out and you can get a cold solder joint....... or you can hold your soldering iron in one spot to press everything together to preheat the material and then slowly add solder keeping the pool liquid, but a bigger gun/iron makes it easier and you don't have to heat everything as long.

Weller Universal 140/100W Soldering Gun Kit W/ Light Pre-Owned | eBay

Find many great new & used options and get the best deals for Weller Universal 140/100W Soldering Gun Kit W/ Light Pre-Owned at the best online prices at eBay! Free shipping for many products!www.ebay.com

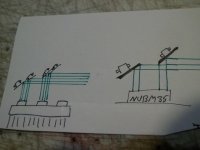

It's not their problem. I checked everything. Everything is soldered very firmly. All connections had the corresponding current B1 B2 B3 B4 B5 B- B+ coming. There was no electricity at the exit itself. With the other BMS, there was no voltage in B3. It was showing 2V. I thought so too, but it's not their problem. Also when I measured the ends of the batteries it showed 24.8V. There was no current at the output of the BMSThis could well be in issue with intermittent connections, you could use one of those spot welder circuits to make your battery connections.