Borislav@87

Active member

- Joined

- Mar 20, 2022

- Messages

- 440

- Points

- 43

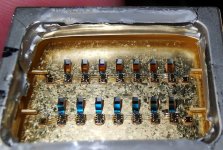

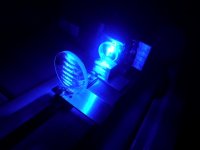

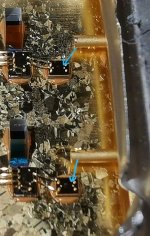

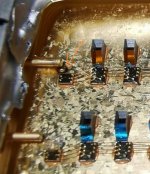

He's dead anyway. I use bare single diodes and they are not that weak. I can try to solder the poles very carefully, but I don't know if it will work. Visibly there is no dust inside. I also used a vacuum pump that is used for photo lenses. I will try to solder them tomorrow. Whatever happens, I have nothing to lose anyway. It doesn't work in this race