- Joined

- May 14, 2008

- Messages

- 468

- Points

- 0

Re: 405nm AR glass lenses - fit AixiZ FEELER

If the o-ring was in a fixed position, i would either work for a red, and prevent parallel focus with a blu ray, or it would work for a blu ray and wobble for a red. And it only povides good support in one position, which would have to be carefully calculated for parallel focus. And if then someone has a diode that is not inserted fully or a slightly different module, it can lead to problems.

Most modules just use a spring. The best lens nut fit so far i saw in a Meredith module. There the threads are much bigger, and the spring is really strong. But it feels just perfect, it has the right amount of resistance and is still smooth enough, and the stiffness is important for short FL lenses.

But i fear a fit as good as that is impossible with an M9x0.5 lens nut..

[/quote]

Wobbling can be avoided by realizing a groove in the outer threaded liner and using a teflon gasket.

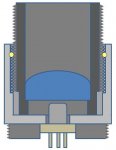

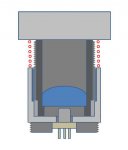

As an example, I have just slightly modified one of the very well made rkcstr drawings; such a soft teflon gasket (it can have square/round section and can be also splitted, as there is the need that the gasket "reacts" with the bottom of the groove) is often used in the aeronautical field. The nut threads go in interference with the gasket, which takes the thread shape thanks to its softness. Also if it wears out after months of use, as teflon is higly friction resistant, it can be easily replaced. The size of the teflon gasket (and of the relevant groove, of course, are specifically designed to avoid wobbling and to give the right friction and pasty feeling to prevent any unintentional focus change.

IgorT said:[quote author=Danjoo link=1212842385/620#633 date=1226411170]Like on this Lens Nut.

If the o-ring was in a fixed position, i would either work for a red, and prevent parallel focus with a blu ray, or it would work for a blu ray and wobble for a red. And it only povides good support in one position, which would have to be carefully calculated for parallel focus. And if then someone has a diode that is not inserted fully or a slightly different module, it can lead to problems.

Most modules just use a spring. The best lens nut fit so far i saw in a Meredith module. There the threads are much bigger, and the spring is really strong. But it feels just perfect, it has the right amount of resistance and is still smooth enough, and the stiffness is important for short FL lenses.

But i fear a fit as good as that is impossible with an M9x0.5 lens nut..

[/quote]

Wobbling can be avoided by realizing a groove in the outer threaded liner and using a teflon gasket.

As an example, I have just slightly modified one of the very well made rkcstr drawings; such a soft teflon gasket (it can have square/round section and can be also splitted, as there is the need that the gasket "reacts" with the bottom of the groove) is often used in the aeronautical field. The nut threads go in interference with the gasket, which takes the thread shape thanks to its softness. Also if it wears out after months of use, as teflon is higly friction resistant, it can be easily replaced. The size of the teflon gasket (and of the relevant groove, of course, are specifically designed to avoid wobbling and to give the right friction and pasty feeling to prevent any unintentional focus change.