Re: 405nm AR glass lenses - fit AixiZ FEELER

I was thinking about the wobble. It's quite annoying. Like Kenom said, the spring is there to minimise it, but i have seen people use teflon tape on metal lens nuts, because it annoys them...

So because of that i fear i will see teflon tape on the custom lenses before long.. :-/

I really have no idea how to fix this safelly without endangering the fit. If we make it too tight, it may not fit all modules, or any at all.

But i just realized two things..

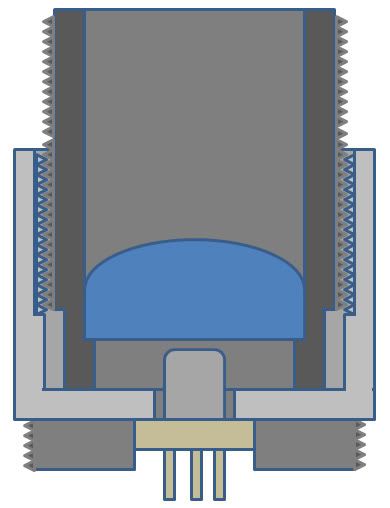

1. The spring will offer some protection from the lens going in too deep. If the lens nut has a protective extension, there is no room for the spring! Unless of course the lens nut was made narrow enough at the bottom for the spring to go around it. But then the diameter could be too low for the lens...

2. Due to the short FL, the lens nut will be deeper in the module than usual. That means that the spring is more compressed, offering more counterforce, and that the lens nut contacts the module with a much larger thread surface area. Both stabilises it a lot.

I just tested with a metal lens nut, in a module, where the threads extend to the bottom. The spring does stop it at a certain depth, and even without a spring, at the same depth the metal lens nut is more stable...

But the latter requires the lens nut to be fully threaded. If the bottom section is left unthreaded in order for it to work in the low quality DX modules, the wobble will return even tho it will be deeper!

So making it compatible with the cheap DX modules might make it less stable..

It would actually be beneficial to have it fully threaded. It would also be a simpler design, and possibly cheaper.

Which bings me back to: Is anyone using the latest DX modules, from the last two or three months? I really hope you all read the warnings and didn't put any expensive diode in there..... I've been avoiding DX modules like the plague for the last few months, just because of this.