Hey, I just have a question for some of you veterans, I think I'm having a problem with component heat transfer. I understand this might be some what obvious but is melting on the thermal tabs a sign that there is poor heat transfer or does it represent another aspect of component failure.

Physically the diodes and fets appear normal but fail common fet and diode tests.

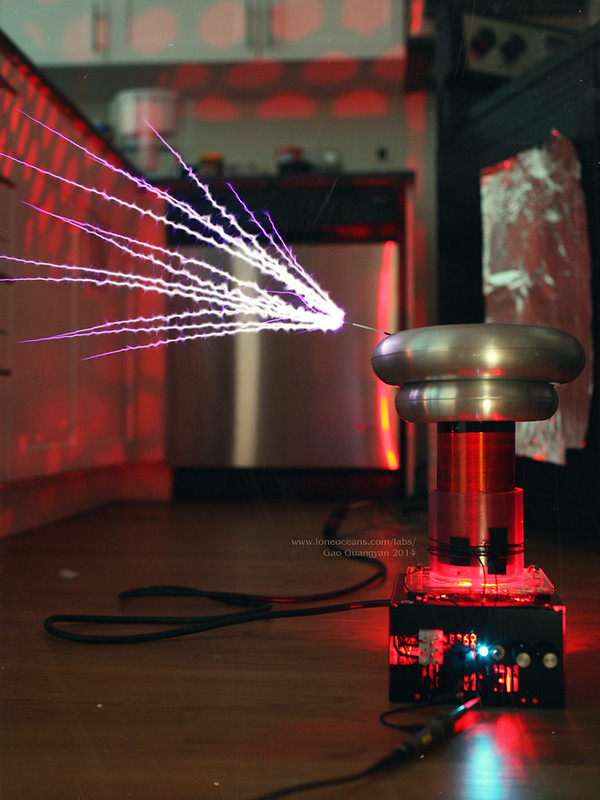

These of course are trash but I think once one failed it started a cascade effect. The coil worked great for 2 weeks until one day after a duty cycle longer then usual the coil just quit. The AL heat sink was barely warm.

To rectify this I ordered new fets and diode's with a much thinner sil-pad. Wish me luck. Bridge rebuild #5.

DownWithUmbrella,

That looks like pretty bad heating on the components!.. and it even looks like the tinning on the metal surfaces has melted, meaning that the components have got really hot. So suppose they were heat sunk to the heat sink with a sil-pad? If so this means either your heat-sinking is severely lacking, or you're getting a lot of losses really quickly in the components.

What sort of setup were you running and what sort of duty cycle? Do you have other parameters such as primary current? Also, what frequency is your SSTC running at?

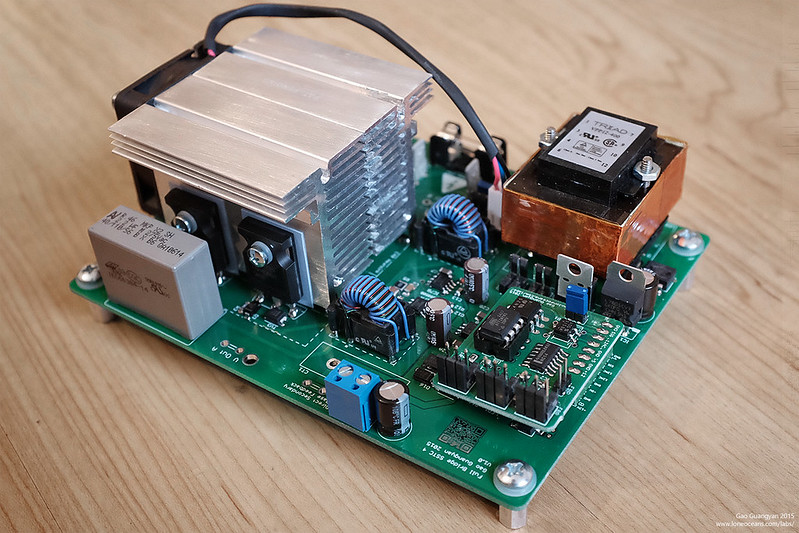

One thing that jumped out to me was that you were using some really big TO264 transistors + separate diodes. What was the reason for this choice? I'm not sure how big your setup is but it looks like an unnecessarily large bridge unless you're driving a -really- large coil, and you'll also need a very robust gate driver. What gate drive voltage and resistors are you using and which gate driver? It's also possible that the FET is not getting into saturation (or high enough saturation) leading to high conduction losses. Even the good old IRFP260/460 should be good enough for a big 1+kW CW coil.

Seeing that this is your 5th bridge, if they all have similar failures, I'll probably try to do something different. Simply replacing components will not be solving your problem and you'll just end up with the same thing. Certainly it looks like your entire setup needs significantly better cooling since it appears that your sink is barely warm yet your components must have got blisteringly hot.

Overall I'd check for:

1. Proper heat-sinking setup. Do you have a photo? One possible option is to ditch the silpad and use separate small heatsinks per switch.

2. High inductance bus and wiring - will cause excessive losses = heat + switch / diode failure. It looks like your components all have long legs meaning they were probably connected with soldered wires? This isn't an ideal setup, probably a good idea to make some sort of laminated PCB or keep your wire loops as small as possible, though I guess that's difficult without a double layer PCB.

3. Is your driver up to task? - what driver are you using? What MOSFET switch are you using? Is is necessary to use such a big Fet?

4. Redundant Diode - good FETs have optimized body diodes these days, adding external diodes may not be required and may be detrimental for a variety of reasons.. in this case it looks like those diodes are very unhappy!

5. Consider perhaps IGBTs - they may be suitable for your use and typically have excellent co-pack diodes, and prices are very good these days!

6. Resonant frequency - may be excessively high - increase switching losses

7. Gate Drive voltage - too high a frequency can cause your gate drive voltage to drop especially if your driver / power supply is not up to it, leaving your switches in sub-saturation

8. GDT - I assume you're using a GDT - is the GDT the right material? Have you scoped the gate voltage during operation?

9. Finally, maybe also try lowering your duty cycle with an interrupter - I presume you're running near CW to get these kinds of heating on the TO264/220 tabs!

Overall for this kind of heating to occur my immediate guess is insufficient gate drive of the switches as the biggest problem + insufficient sinking and high duty cycle.

Need to have it on hand to investigate properly though since I'm just making wild guesses but good luck!