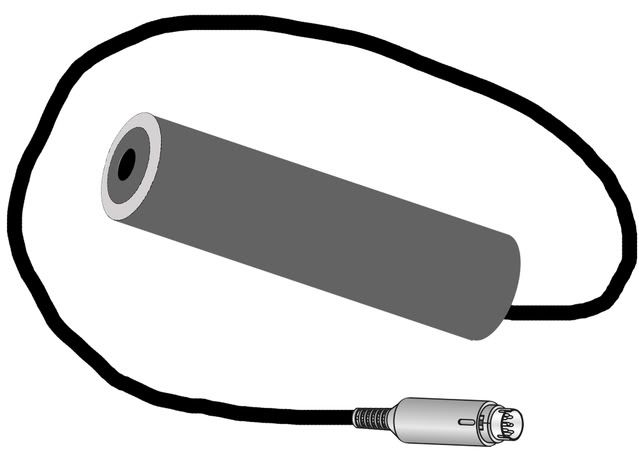

rkcstr that looks very good to me - exception being that Kenom's spec should be used for the connector to the Dorcys, because he knows what fits.rkcstr said:Here's a mockup of what I was thinking:

But... are there 2 connectors here? one at each end of a 2-wire cable? that's what it sounds like if there's a connector on the box. That means a loose cable to ship around or get lost (I've seen those photos of Ken's workspace, and mine is sometimes similar) :

Suggestion: no connector on the box - just cable out, terminated with whatever Kenom wants to plug into his end. I mean plug into the Dorcys. ;-)

Hey, what about just using a standard audio cable - with, say, an RCA jack?

Alternatively, rkcstr could make a cable that plugs into whatever he feels like on his end, leaving the other end unterminated; then Kenom can add whatever he wants on the other end! Still leaves us with a loose and non-standard cable though... I like the standard audio cable better.

DanQ