TaterMay Yes. Several people have bought them from me already or from Flaminpyro for use with these 44 diodes.:wave:

The SXB-V8 can boost up to 5.5A for these diodes no problem. Plenty of Power.

IMR battery is a Must.

That should be more then enough current for anyone but if need be until the new

10A "SXB-V8 Plus" version comes out in a few months you can dual a pair of SXB-V8 drivers for up to 10A+ Boost output current.

Not that anyone needs 10A now but iam just saying its possible to dual them.

You will be fine with 1 SXB-V8 though. No need to dual them for this diode. Not alot of heat comes off the driver for 4A+ but still needs to be heatsinked well. I guess one can dual them to reduce the heat greatly but its not worth spending the extra money on a driver just to do this.

But if someone wants to do this i will give a discount on the second drivers if that is your purpose.

You will need IMR cells and a switch that can take the current draw which will be 7A+... You will need to run short wire and use 22AWG or lower AWG.

Jeff is out of town right now so if anyone needs a SXB-V8 until he comes back contact me.

He has not had a chance to change the Text on Max rating in his thread on some of the SXB version so ask before you purchase if the version you are interested in is able for 4A+ until he updates. So if you have any questions Please Pm or email me.

Having said that I would suggest going buck (SXD-V3) or whatever driver you want to go with and grab one from DTR store or Flaminpyro "When hes back". With this high of current unless you know your host/host switch and wiring can take the current draw boost should be your second option to Buck.

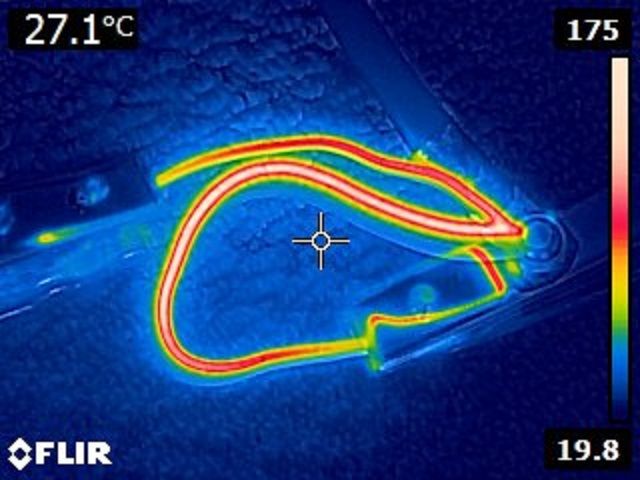

Here is the build i did for a customer a couple weeks ago using the SXB-V8 Boost Big Boy 5A+ version.

This was after 2 minutes being on. It peaked at just under 7W.

The SXB-V8 Boost driver was set for 4.7A

and the Big Boy SXB-V8 version for this host:

Since the SXB-V8 Big Boy version driver went into the pill spot in the host i added a copper heatsink on the chip and a small copper heatsink on the flat pack diode to help with cooling.

It was more then enough.

But any of the SXB-V8 version, once you heatsink them they run cool.

This build takes 3X 18650 cells in parallel. So it was a Great choose for the SXB-V8 Boost. I used 3x LG HE2 18650 IMR cells to power it and worked Great.

But As i said i think Buck is the way to go for these diodes.

The SXD-V3 Buck also has Ramp Up on it available which can be set up to ~30 second right now "More if needed". This is a Special request so you would have to come to me for this option. Here is an example:

This feature was designed for the C-mount 660nm diodes a while back so they dont get hit with full current and thermal shock the diode and a few Lab laser projects that someone needed done. I think now with these blues and especially with the 07E diodes or even the M462nm or Nichia 462nm diodes that people push them passed the roll back so they can squeeze out some extra nm out of the diode, a nice longer ramp up for that would be a nice touch even though typical blue diodes are robust your pushing your luck passed the roll back.

You can actually see the diode changing Wavelengths on the O7E going passed the roll back when you have ramp up on it.I must say too it looks cool too.

But this is not the thread to talk about the 07E. Just excited.:shhh:

Might be a nice touch for the 44 diodes too for some people.

But most just want full power instant which is fine too.:beer:

I'll take a video of 60A through 14awg when I get back to the states if I remember. I'm pretty sure it'll get floppy and start smoking.

Remember, wire insulation also insulates against heat. So you cannot feel the real temperature of the copper. Running the wire at obscene loads may not instantly smoke the insulation, but it WILL degrade it over time.

The length only affects the voltage drop (and parasitic inductance, etc.). The heat per unit length will remain the same.

No. Strand count has no effect on the current carrying capability. The AWG number is a measurement of the cross-sectional area of the copper, and therefore the resistance per unit length.

Wrong. It has zero effect. The equation is power(heat)=I²R. R is the resistance of the wire which is a constant, and I is the current through the wire. This means if you double the current, you get 4 times the heating. If you triple the current, you get 9 times the heating.

The leads to a 600V 10A load will have identical wire heating profile as that of a 2V 10A load.

Yep.

The voltage rating depends on the insulation type and the insulation thickness. Most insulation is rated for 300V or 600V. Some very small wires in data cables might have insulation only rated for 30V. Basically any 14awg wire will be rated for at least 300V.

That being said, it's a VERY conservative rating. 300V is tested to withstand 3kV, and 30V is tested to withstand >1kV. Actual instantaneous breakdown voltages will be much higher than this, still.

I worked on an extrusion line in a custom wire factory for 3 years. I know a thing or two.

No need for a video Alex. I believe you.

What i dont think is that the wire i have will have a problem. "Bellow i give you why." But can i send you some of this wire to run 60A through it when you get back.? Iam interested to see what would happen. I only have 40A MAX available to me until i decide to buy one of those nice 0-80A 0-15V supply's on ebay. Cant seem to snatch one up cheap yet in good condition.

You know what, ill give you a link to order from and ill PP you the money.

PM later incoming. Plus i need your help on something.:shhh:

I agree with you that it will degrade overtime more then likely. As i said under the condition iam using the wire i have i dont see 60A being a problem. But because i dont know the true specs of this wire other then it says 55A Rated and from the 40A i put into it i cant say if running it for long periods of time will degrade or burn the wire. Ive ran it on my Tiapan for maybe 30 minutes and it was fine at 35A-40A...It was Warm sure but not hot. I know insulation holds in heat but i would surely be able to tell the difference between it being warm and burning hot.

But doesn't the voltage drop cause more heat.? I swear when i use 1 foot vs 5 feet its like the wire doesn't even get warm.

What is the purpose then of high stand count then.? I was told that it gives better current handling.?

Well maybe this wire i have isn't 14AWG inside. After all its from overseas so they are not probably to standard. I will measure it tonight and update you on this. From what i real 14AWG is 1.628mm Correct?

So that couple be the answer that although it says 14AWG it night not be.

Dint realize that. I thought that the voltage also has effect. Learned something new here.:beer:

Yes this wire says its 600V on it.

I know you know your shiznick.:beer:

I need a pointer push button switch for 30 amps, not sure i will find that.

Chris You dont need a 30A Switch if you are using the SXD-V3. Is this the tri build.?

If so you can have the tail cap be a solid connection and use the enable pin as the On/off switch and use as little of a switch you want to bridge the connection. PM me if you want to talk about it. I can help you on this.

Its very easy to do if your host is setup in a way to use it.