Man, I just don't feel comfortable with pushing anything anywhere near 4 watts without that extra full copper back half. Since I've been monitoring case temp, I've seen what a significant role it plays in dissipating the heat. I just don't even want to chance it with a $150 diode. But it very well may be able to take it just fine. I guess we will see! Are you mounting the driver straight to the diode?

Sorry I didn't see your question, been busy.

No my driver is mounted in it's own housing behind the diode module.

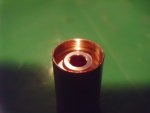

But I do have mine with a regular aluminum back because I used big wire that wont fit through the solid copper back hole and drilling it out would take out most of the little copper pedestal that makes the thermal contact with the diodes back.

What I did was I filled it with heat sink putty to thermally bond the back of the diode to the 12mm aluminum back half.

It's working like a champ, awesome color and a good burner. The divergence is better than the 44 diode as well.

The solid copper backs are a good idea, they work best with the silicon wire DTR uses, but I would also put a little heat sink compound around the pedestal to make contact with the rest of the back of the diode if you are pushing them harder than 3.5 amps.

Want a laugh?

My original host had a little spring pcb battery board that decide to develop an intermittent open, after tearing it down twice and discovering it was the board I gave it the hammer treatment and put the works into a big ugly caveman portable test host.

Point is the aluminum back half filled with heat sink compound transfers heat just fine as I run this ugly host for many minutes and it all gets warm like it should, but the full copper back lets you take it apart and is the way to go.