Scotoma

0

- Joined

- Aug 11, 2009

- Messages

- 21

- Points

- 0

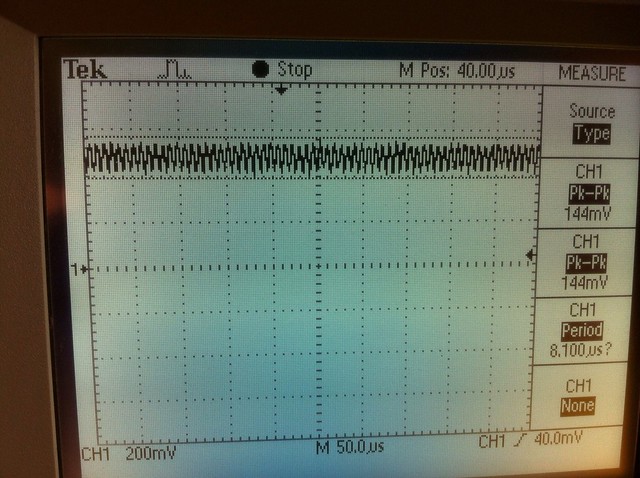

So, just to make sure, when deciding on the current for these drivers, we should take into account a 40 mA (rhd) to 152 mA (tsteele) ringing? In other words, the output might go as high as 20-76mA above what it's set to? Thanks for troubleshooting that startup spike away tsteele :beer: