Kizdawg

0

- Joined

- Feb 7, 2012

- Messages

- 977

- Points

- 0

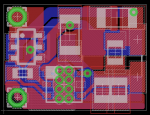

Well got some 22uf caps for the OVP boards and whipped up a few yesterday. I must say it's tedious work.. hehe but I have never made more than one or two at a time this time I made 3 and then 6 and only had 1 bad connection on the outside zener that was an easy fix with the iron. I also wanted to see if this flikr thing works ok..

IMG_4082 by Kizdawg, on Flickr

IMG_4092 by Kizdawg, on Flickr

IMG_4082 by Kizdawg, on Flickr

IMG_4092 by Kizdawg, on Flickr

Last edited: