- Joined

- Aug 25, 2010

- Messages

- 533

- Points

- 63

Hi to all.

This is my first complete and almost well done review for a laser build, so be nice please

Starring two awesome items:

- The DTR 16X BDR-209 Diode In Copper Module With Driver @ 700 mA and 405-G-2 Glass Lens;

- The Sinner's Cypreus II copper host.

For this build I have used three new special guests:

- A new digital WELLER WSD81 SE 80W soldering station;

- A 7W Laserbee power meter with Ophir head;

- An handmade reamer.

So, let's start!

The soldering station:

The 7W Laserbee:

The handmade reamer:

This item was built usying a japanese white marker and a extra-fine sandpaper.

I put also some pre-lim paste over the sandpaper, a very gently surface cleaner.

The total diameter is about 11.5 mm, but I can easily vary it adding more coils of sandpaper.

I use this reamer to create a very smooth mirror surface into the heatsink hole,

to have a perfect contact between the parts.

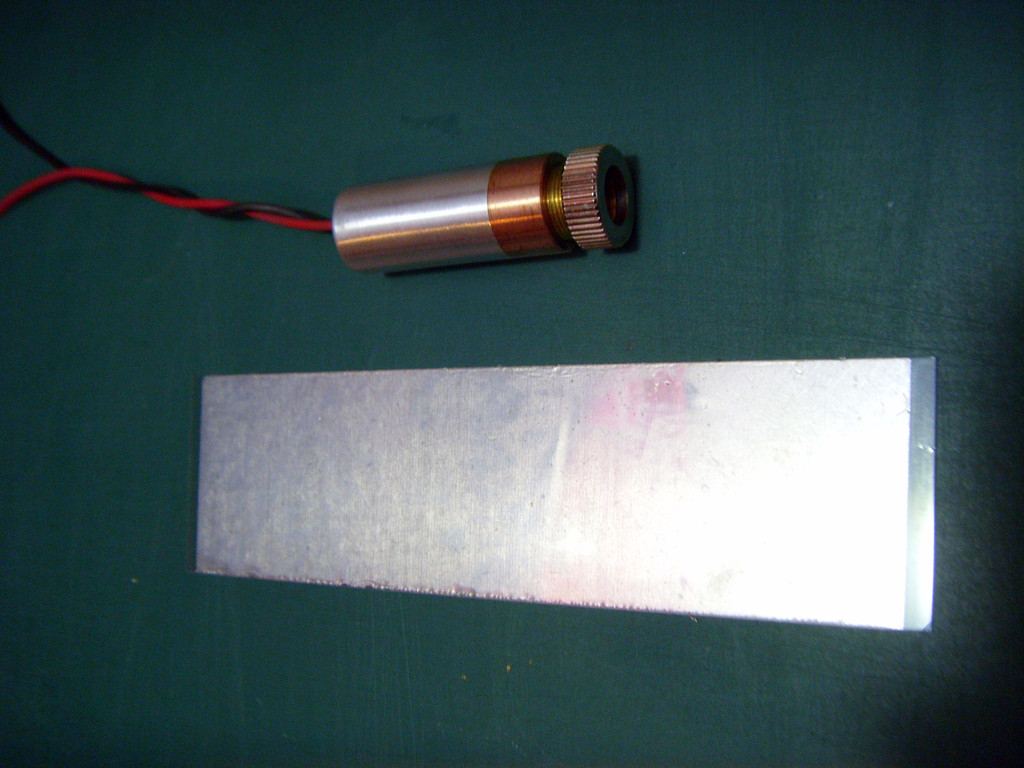

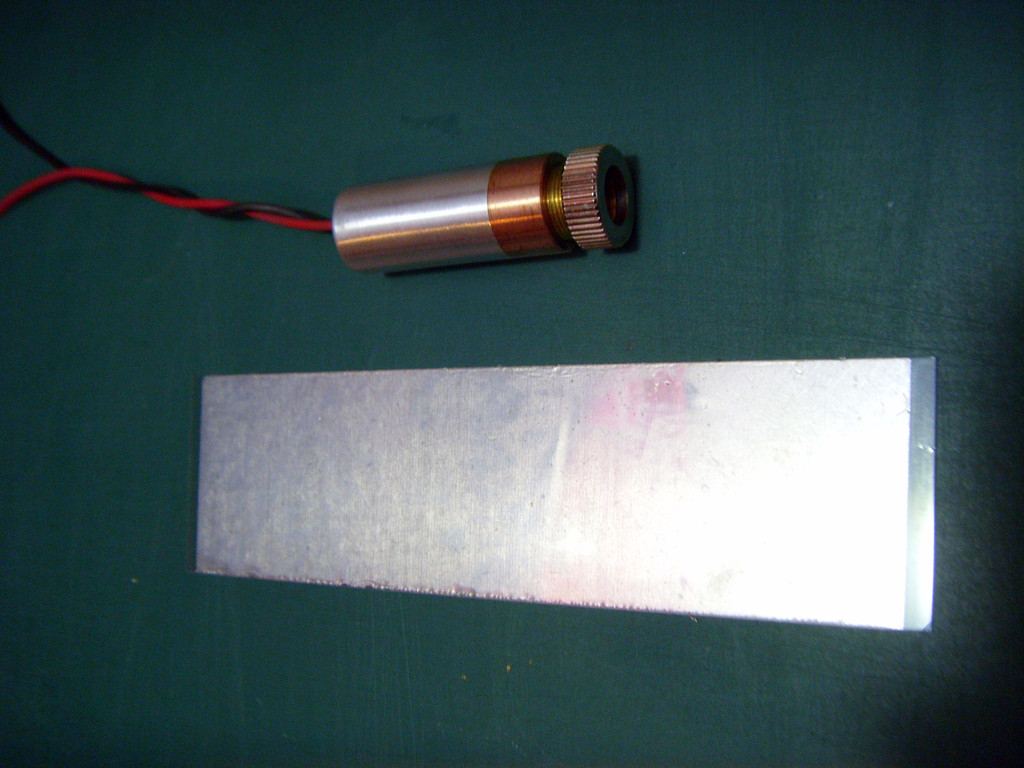

The violet diode and the 0,05mm Indium foil:

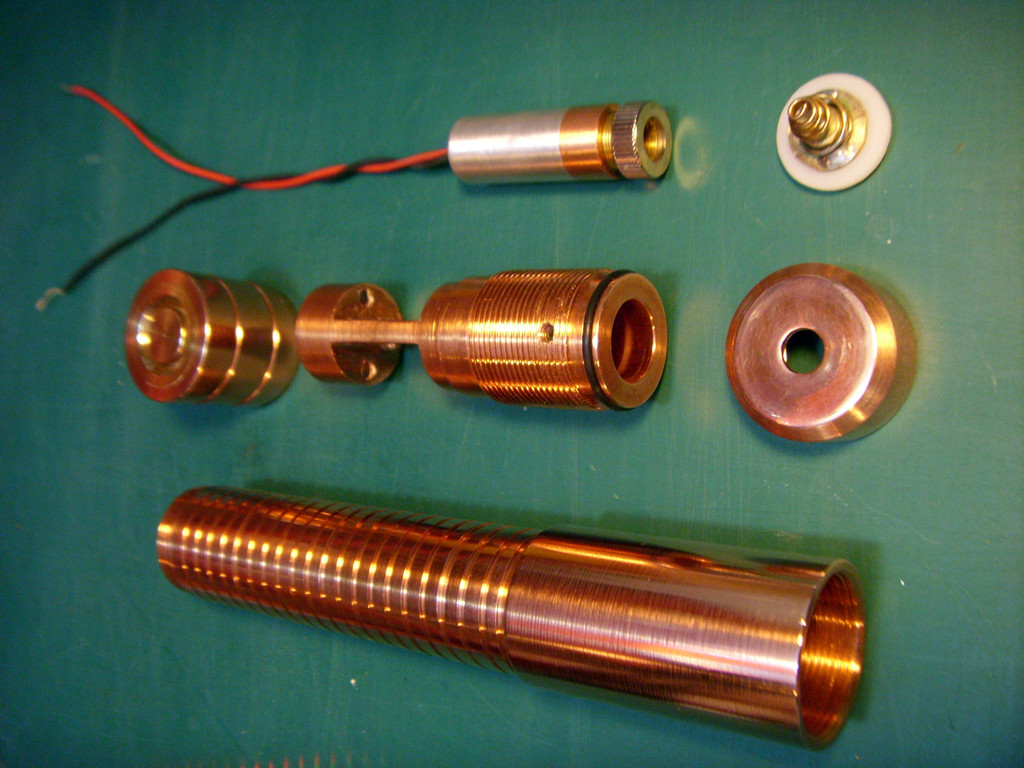

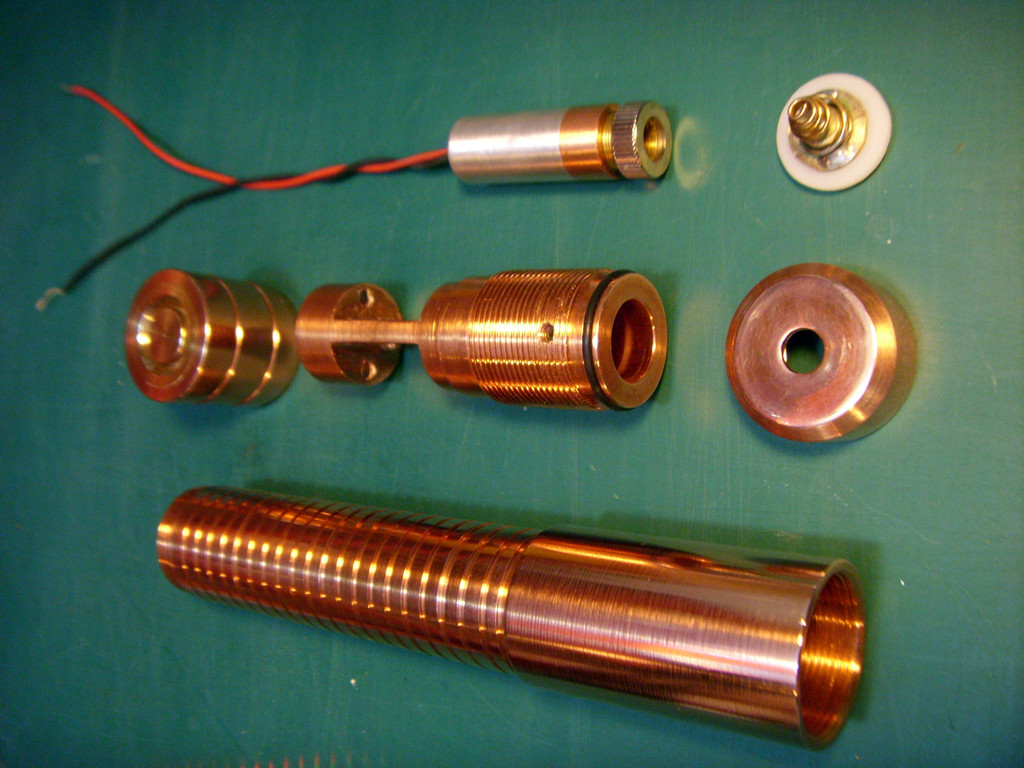

All the needed parts:

Diode module gently scrubbed with extra-fine sandpaper:

All the contact parts were extra-cleaned with the best cleaning liquid fluid available today in the market:

Diode with Indium foil wrapped around, ready to be inserted into the heatsink:

Diode inserted with good pressure into heatsink.

No need to use the set screw.

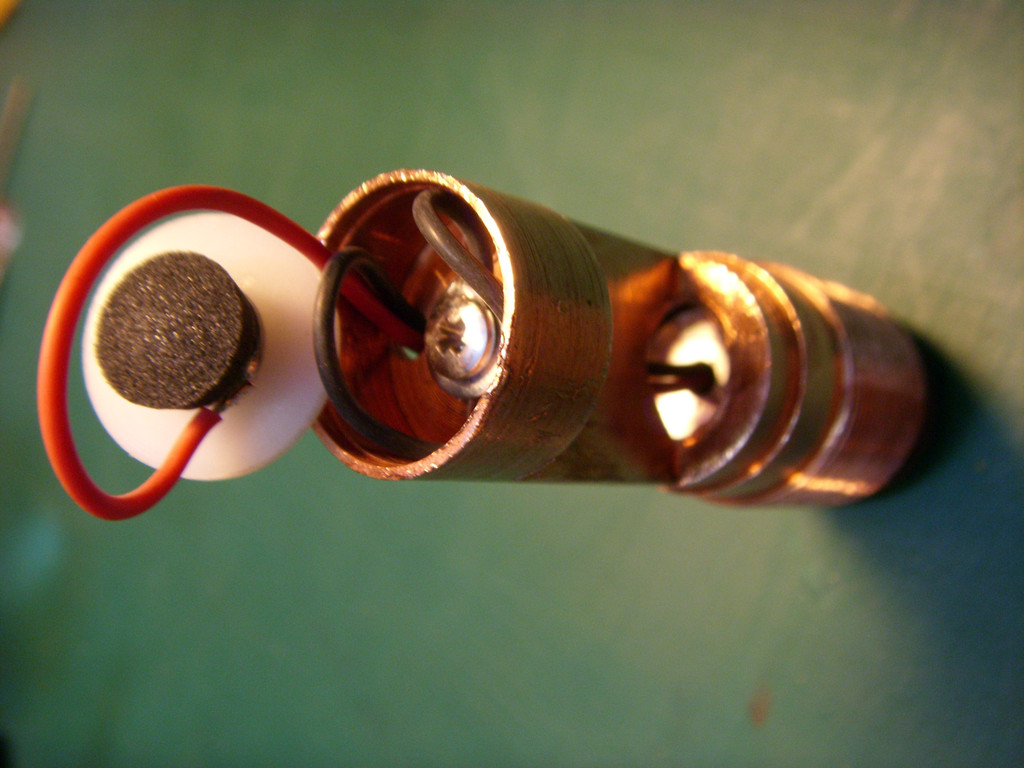

Crown pressed into focus ring with the help of a vice:

Soldering and connect the inside wires:

In order to avoid any possible short, I have added a soft piece of rubber between the screws:

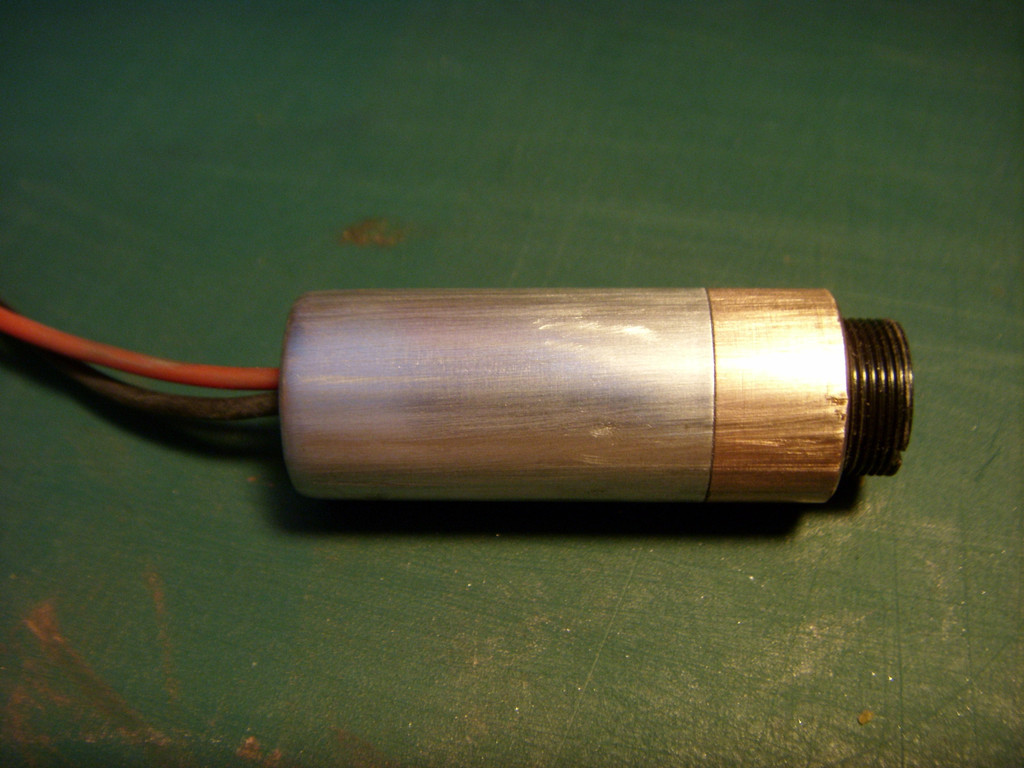

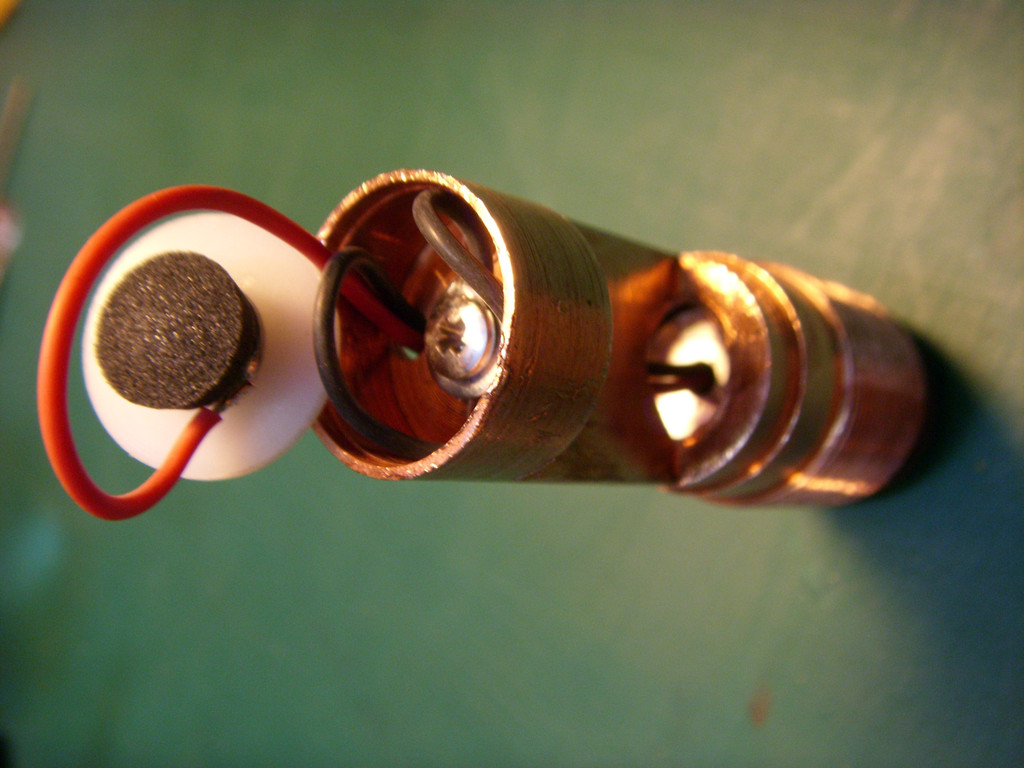

Assembled heatsink:

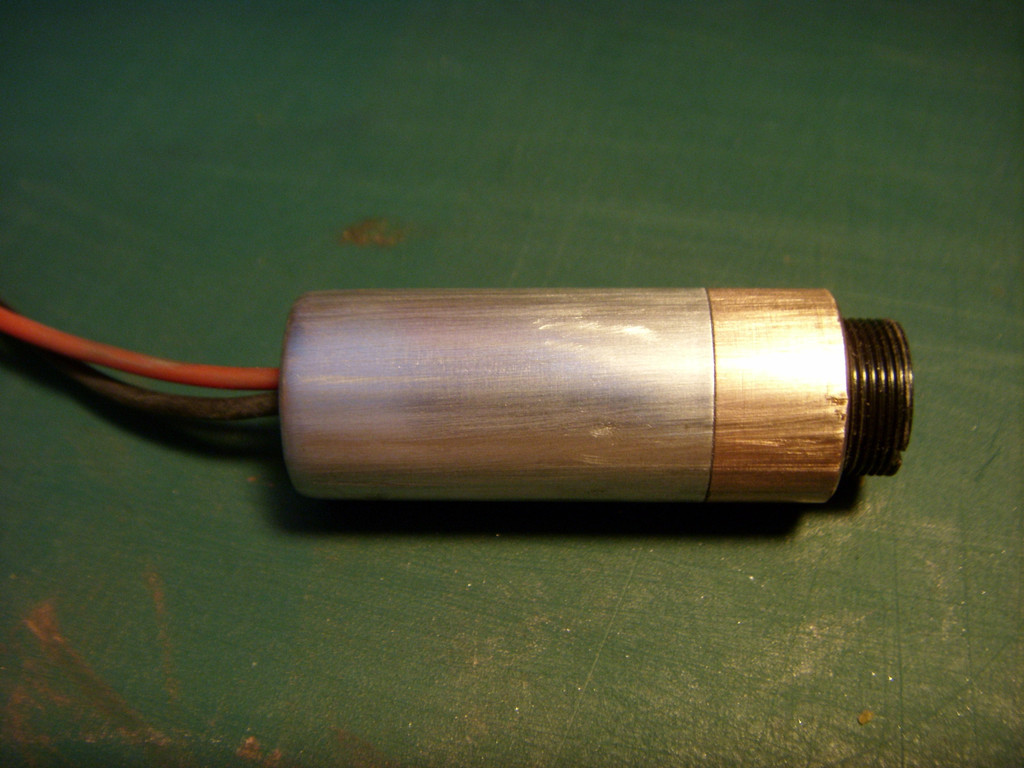

The final product:

Cypreus II on Manfrotto minipod:

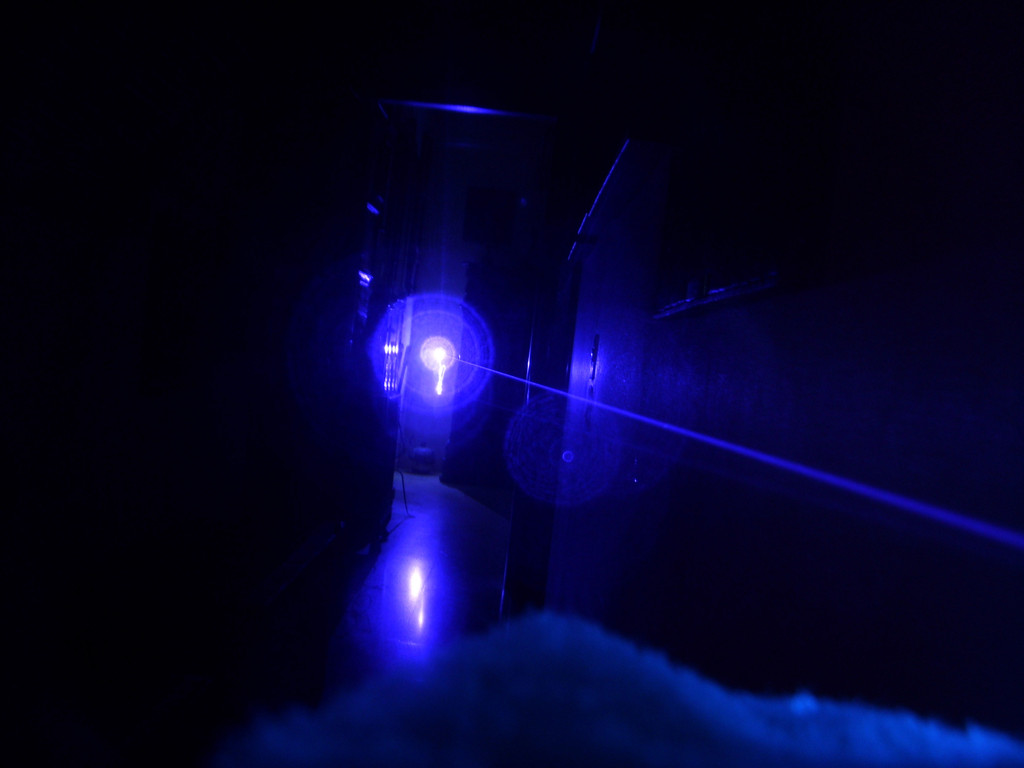

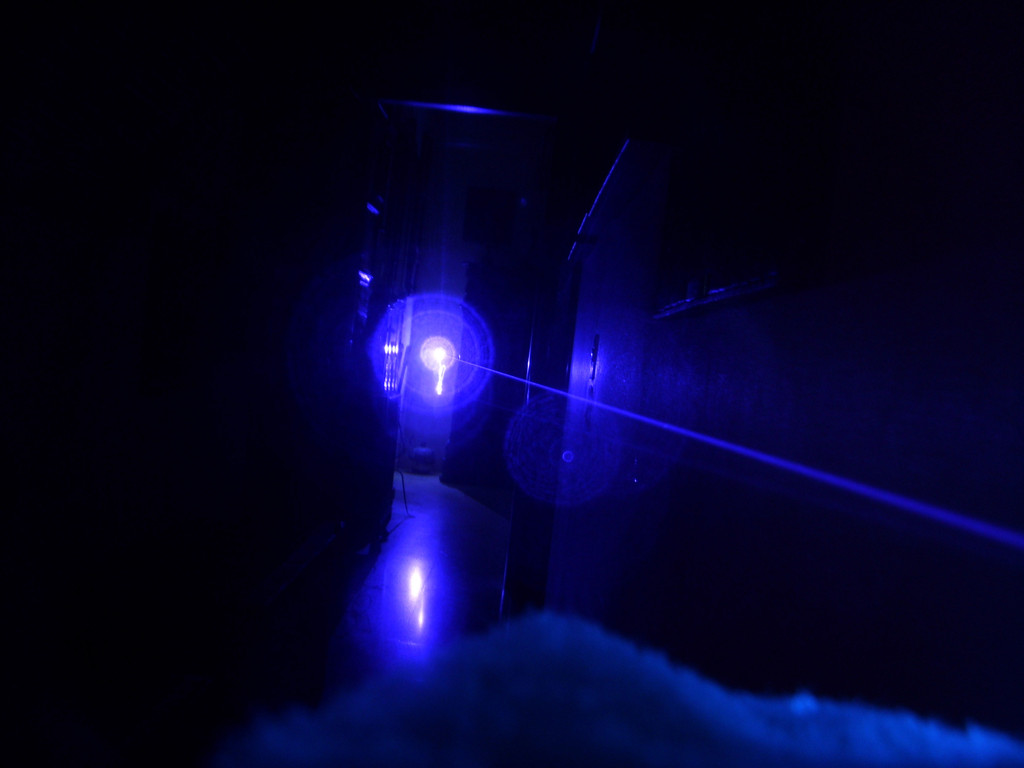

The beamshot:

The violet beam is very difficult to capture with a camera, especially to obtain the right colours.

This shot looks like a blue laser, but really is much more violet.

I was forced to use a 15 sec long exposure to have a decent amount of light.

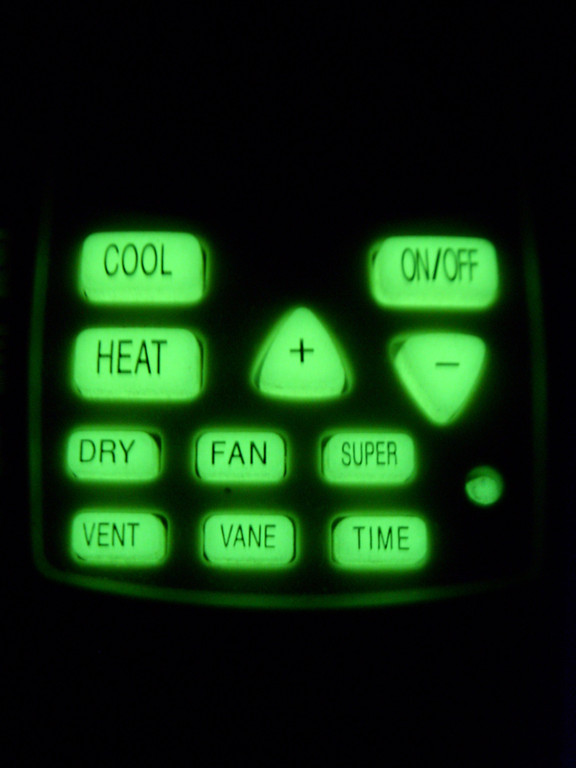

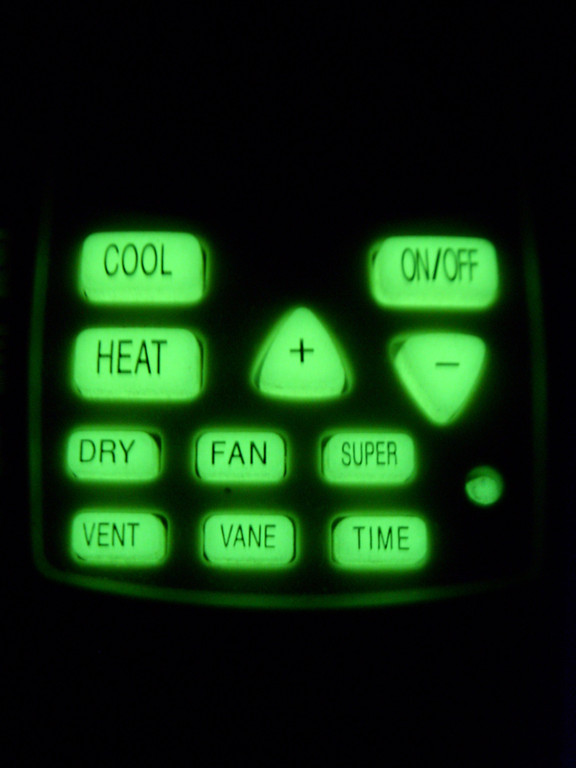

The fluorescence ignition:

Those air-conditioner remote control buttons seems to be backlighted, but they are off!

This is a pretty fast reaction of fluorescent materials when affected by a violet frequency.

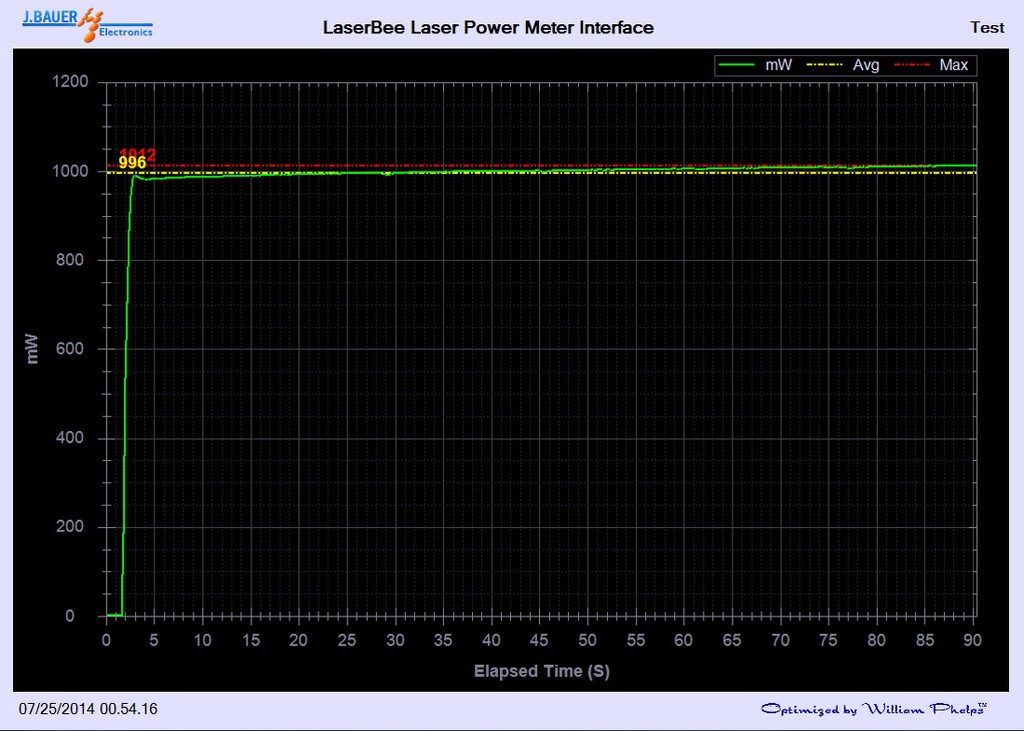

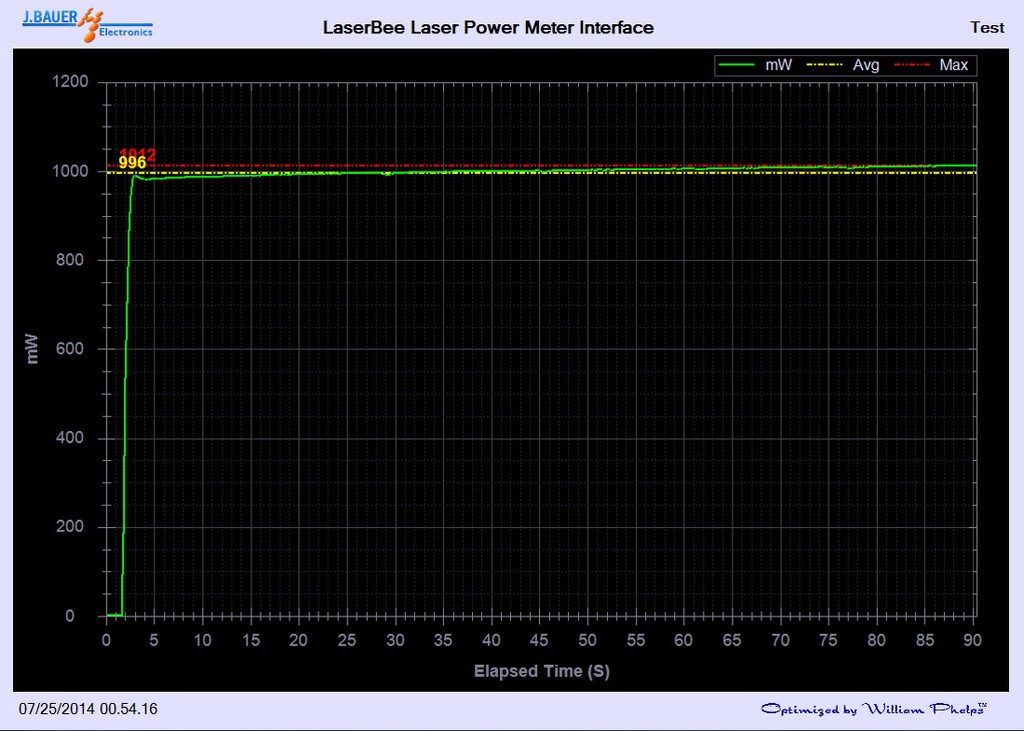

The performance graph:

What an awesome diode! It is very stable, and tend to slightly increase output in the time!

I have limited the test to 90 seconds, but with Cypreus II surely I will have a longer duty cycle.

After 90 sec the copper become slightly warm, so Indium foil and copper parts are doing their dirty work!

Finally, the video:

The host was placed at about 3.5 meters from the mouse pad (yes, was a

professional mouse pad ... :yabbem .

.

The surface began to smoke immediately! Also the match light at once.

The dot is so powerful, tiny and precise that ignite light wood pretty fast.

Goggles is a must, this is really a dangerous laser !

Conclusions: this is a masterpiece, powerful, precise, rock solid and made with a high craftsmanship.

I wish to thanks a lot two guys that allowed the creation of this project: DTR and Sinner.

See ya soon for my next reviews .. stay tuned! :beer:

Richard.

This is my first complete and almost well done review for a laser build, so be nice please

Starring two awesome items:

- The DTR 16X BDR-209 Diode In Copper Module With Driver @ 700 mA and 405-G-2 Glass Lens;

- The Sinner's Cypreus II copper host.

For this build I have used three new special guests:

- A new digital WELLER WSD81 SE 80W soldering station;

- A 7W Laserbee power meter with Ophir head;

- An handmade reamer.

So, let's start!

The soldering station:

The 7W Laserbee:

The handmade reamer:

This item was built usying a japanese white marker and a extra-fine sandpaper.

I put also some pre-lim paste over the sandpaper, a very gently surface cleaner.

The total diameter is about 11.5 mm, but I can easily vary it adding more coils of sandpaper.

I use this reamer to create a very smooth mirror surface into the heatsink hole,

to have a perfect contact between the parts.

The violet diode and the 0,05mm Indium foil:

All the needed parts:

Diode module gently scrubbed with extra-fine sandpaper:

All the contact parts were extra-cleaned with the best cleaning liquid fluid available today in the market:

Diode with Indium foil wrapped around, ready to be inserted into the heatsink:

Diode inserted with good pressure into heatsink.

No need to use the set screw.

Crown pressed into focus ring with the help of a vice:

Soldering and connect the inside wires:

In order to avoid any possible short, I have added a soft piece of rubber between the screws:

Assembled heatsink:

The final product:

Cypreus II on Manfrotto minipod:

The beamshot:

The violet beam is very difficult to capture with a camera, especially to obtain the right colours.

This shot looks like a blue laser, but really is much more violet.

I was forced to use a 15 sec long exposure to have a decent amount of light.

The fluorescence ignition:

Those air-conditioner remote control buttons seems to be backlighted, but they are off!

This is a pretty fast reaction of fluorescent materials when affected by a violet frequency.

The performance graph:

What an awesome diode! It is very stable, and tend to slightly increase output in the time!

I have limited the test to 90 seconds, but with Cypreus II surely I will have a longer duty cycle.

After 90 sec the copper become slightly warm, so Indium foil and copper parts are doing their dirty work!

Finally, the video:

The host was placed at about 3.5 meters from the mouse pad (yes, was a

professional mouse pad ... :yabbem

The surface began to smoke immediately! Also the match light at once.

The dot is so powerful, tiny and precise that ignite light wood pretty fast.

Goggles is a must, this is really a dangerous laser !

Conclusions: this is a masterpiece, powerful, precise, rock solid and made with a high craftsmanship.

I wish to thanks a lot two guys that allowed the creation of this project: DTR and Sinner.

See ya soon for my next reviews .. stay tuned! :beer:

Richard.

Last edited: