Pman

0

- Joined

- Nov 28, 2012

- Messages

- 4,441

- Points

- 113

Why were those sizes specifically picked? You must have had a reason J.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You know, some square copper diode modules would be nice, the backs could use 4 screws for superb heat transfer.

They would be great for light show builds and nuts like me who want to square 2 or 4 together in a box build, but for beam combining and light show boxes they would be great.

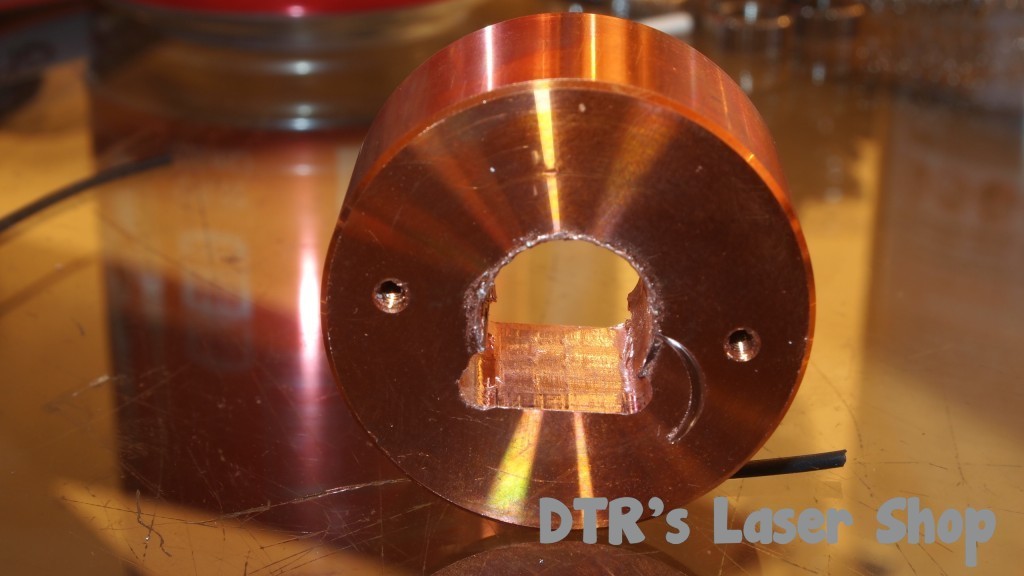

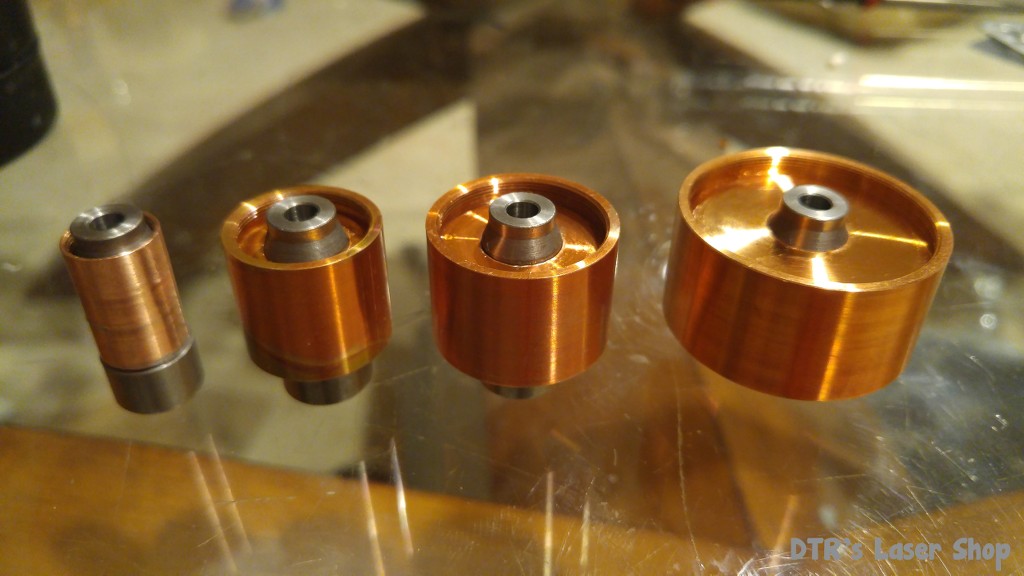

Finally spent some time this week getting my mill I bought late last year up and running. This thing is awesome for making alterations to the modules I have in stock. I been making diode press sleeves. I am waiting on some larger milling flutes so I can mill out a small shelf in the back of the copper back halfs for drivers to be sinked to and I will be able to offer the big boys with drivers internal as well.:eg:

Finally spent some time this week getting my mill I bought late last year up and running. This thing is awesome for making alterations to the modules I have in stock. I been making diode press sleeves. I am waiting on some larger milling flutes so I can mill out a small shelf in the back of the copper back halfs for drivers to be sinked to and I will be able to offer the big boys with drivers internal as well.:eg:

Hi,

This is what we need a shelf milled into the back for a driver seat. I have a few sinks that i had made from a local shop for one of my projects. They came out well in AL and now going to try CU and have some other sinks made.. These are my AL sinks ...

Rich