xStatiCa

0

- Joined

- Feb 7, 2010

- Messages

- 360

- Points

- 0

I wonder how long will it run at that amperage in a closed area (like in a host).

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Awesome! Congrats.

I got my station and parts yesterday ... I think I managed to kill the TI chipIll try replacing it today.

What have you done wrong?

How did you soldered the other boards?

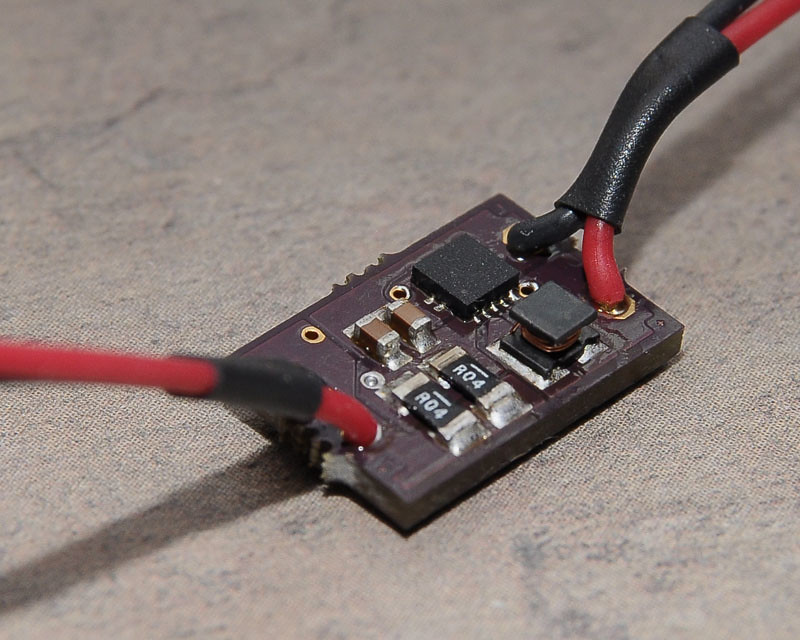

I did them by hand with two soldering irons. For the QFN I put a small pillow of solder on the chip's thermal plane and the pin pads on the board. I heated the ground plane on either side of the chip until it reflowed into place. Then I did the blob meathod to reflow the solder on the pads.

Success. Measured 1.14 Amps w/ 4V dummy load! Temp only 49ºC(120ºF) @ about 30 seconds. Hell yeah!

I had to replace the TPS ... luckily I ordered 3. I transplanted everything to a new board and did not use paste. I pillowed the pads with regular 60/40 solder applied flux and gently put the parts on top. I used higher temp but held the air nozzle further away and it re-flowed perfectly. The joints are all so perfect.

jib77;

Good job on the new board.

I have some quality #18650's if you need some to try.

I live in Farmers Branch.

LarryDFW

congratz!

well, looking at the inductor I see that is not possible to put an effective heatsink, because the inductor is somehow tall..

will it pump more current? heatsinking? maybe adjustable output (pot)? ^^

hell yeah, gratz again