- Joined

- Feb 25, 2010

- Messages

- 1,643

- Points

- 113

The Sky Blue Ramjet - Electrons in....

Photons OUT !!

Time for another yet experimental build. See the pics. This one will be different from other experimental builds I have posted....as it will use mostly off-the-shelf parts.

I decided to use a very common, inexpensive, 2C Aluminum Maglite as a host. The black color - 2CCO16 Maglite Flashlight. Maglite makes a great product. Maglite's are solid built and all are side clicky. All Maglite's have a larger Bell head which lends itself to a reasonable diameter for additional corrective optics for beam shaping.

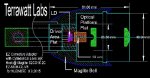

While this build is not in the Combiner Class...I suppose it could be called an "Aspect Corrected Optics class". I state this because the LD output will be corrected with a set of Telescope optics, being a Plano Concave Cylindrical lens and a Plano Convex Cylindrical lens. The magnification I use is 6X. These optics will perform aspect correction for a too-wide beam. The output will not be a perfect box....but close.

I also propose that this design could be used with other multi-mode wide beam diodes. I am sure this concept could be used to correct the Red P73 or Oclarro 63193 and possibly the Green 520 nm NDG 7475 and or the Blue 445nm NDB7A75.

The Sky Blue Ramjet build (SBR) will use one (1) NUBM07E ( @ 465 nm ) diode coupled with a G2 lens. I will use two (2) 25500 LiPo cells for power delivering a nominal 8.4 VDC to the driver. Current plan is to use the SXD-V8 4A fixed - Lazereer driver. I hope to achieve a output of 4.5 W....AFTER optical correction ! That is a beautiful amount of Sky Blue !!! Hopefully ...hammered into a tight beam !

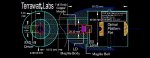

With this build, there will be only one custom component: The Aluminum Heat Sink-Optical Platform insert (HSOP). See the drawing V8. I have started with a 2" ( 50.8mm)O.D. solid Aluminum rod stock ...which is now machined down to 3.189" (81mm) in length.

The Ally stock will be milled down to 48 mm in diameter... with a short portion left at 50.8 mm in diameter. This 50.8 mm ridge will be used as a lock area which will be captured by the original Bezel ring when it is screwed onto the Maglite bell front.

The back section of the unit will be machined down to 26.3 mm in diameter for placement within the bell recess pocket and will contain the CU module/LD and the driver. The LD will be press fit mounted in a CU Module and the module will eventually be set in a 12mm centered bore in the HSOP.

The most unique feature of the Heat Sink-Optical Platform insert ( HSOP ) is that it is home to all the major components...except the batteries and the I/O switch. The plan is to machine flat the front and back sections. The Front section will serve as the optical platform for the Cylindrical lens placement and the rear platform will serve as the mount flat for the driver.

The Cylindrical lenses will be epoxied to the front flat section and the driver will be set with Artic two component epoxy to the rear flat section.

As is typical, the CU module will capture/position the LD and the Collimation lens....which will then be inserted and secured with a set screw into the non-flat machined segment of the HSOP.

So...all the goodies ride on the Heat Sink-Optical Platform insert....including the V8 driver. A short portion of the HSOP will extend out past the bezel lock ring. I wish all optics would ride within the bell...alas....this cannot be... due the separation demanded between the cylindrical lenses.

I have attached pics of the start of the project. I am waiting on DTR/Lazereer for the NUBM07E diode. I really wanted to present a build....that may also serve as a obtainable and doable design for those wanting to enter the area of Aspect Corrected Optics class. This is especially desirable in that so many of our new, high power diodes are multimode...and will benefit greatly from corrective optics !! We can hammer the beam....from a thin bar....into a box/rectangle....where width....is only slightly greater than height !!

The attached pics are self explanatory...I just removed the components where the Xenon Bulb was mounted. With these components gone, the pic shows the host open top where the +/- hook-up points are located.

The thin metal tab extending up is the negative supply for the driver and the 6mm x 6mm metal square located in the centre of the recess is the switched positive supply for the drive. Very straight forward !! Driver gets connected to these points and the LD gets connected to the driver !!

While this host was designed for two (2) standard C cell batteries...the geometry of the 25500 LiPo is exactly the same...so no modification needed for the battery portion of the host !

SO....there you have it....This project started out some time ago as the " EZ-Adaptor "....which was an add-on for just the Cylindrical optics on to any handheld. Connectivity problems with that initial design where a roadblock. The SBR is a work-around....Enjoy the build..... and stay tuned !!!:na::na:

Photons OUT !!

Time for another yet experimental build. See the pics. This one will be different from other experimental builds I have posted....as it will use mostly off-the-shelf parts.

I decided to use a very common, inexpensive, 2C Aluminum Maglite as a host. The black color - 2CCO16 Maglite Flashlight. Maglite makes a great product. Maglite's are solid built and all are side clicky. All Maglite's have a larger Bell head which lends itself to a reasonable diameter for additional corrective optics for beam shaping.

While this build is not in the Combiner Class...I suppose it could be called an "Aspect Corrected Optics class". I state this because the LD output will be corrected with a set of Telescope optics, being a Plano Concave Cylindrical lens and a Plano Convex Cylindrical lens. The magnification I use is 6X. These optics will perform aspect correction for a too-wide beam. The output will not be a perfect box....but close.

I also propose that this design could be used with other multi-mode wide beam diodes. I am sure this concept could be used to correct the Red P73 or Oclarro 63193 and possibly the Green 520 nm NDG 7475 and or the Blue 445nm NDB7A75.

The Sky Blue Ramjet build (SBR) will use one (1) NUBM07E ( @ 465 nm ) diode coupled with a G2 lens. I will use two (2) 25500 LiPo cells for power delivering a nominal 8.4 VDC to the driver. Current plan is to use the SXD-V8 4A fixed - Lazereer driver. I hope to achieve a output of 4.5 W....AFTER optical correction ! That is a beautiful amount of Sky Blue !!! Hopefully ...hammered into a tight beam !

With this build, there will be only one custom component: The Aluminum Heat Sink-Optical Platform insert (HSOP). See the drawing V8. I have started with a 2" ( 50.8mm)O.D. solid Aluminum rod stock ...which is now machined down to 3.189" (81mm) in length.

The Ally stock will be milled down to 48 mm in diameter... with a short portion left at 50.8 mm in diameter. This 50.8 mm ridge will be used as a lock area which will be captured by the original Bezel ring when it is screwed onto the Maglite bell front.

The back section of the unit will be machined down to 26.3 mm in diameter for placement within the bell recess pocket and will contain the CU module/LD and the driver. The LD will be press fit mounted in a CU Module and the module will eventually be set in a 12mm centered bore in the HSOP.

The most unique feature of the Heat Sink-Optical Platform insert ( HSOP ) is that it is home to all the major components...except the batteries and the I/O switch. The plan is to machine flat the front and back sections. The Front section will serve as the optical platform for the Cylindrical lens placement and the rear platform will serve as the mount flat for the driver.

The Cylindrical lenses will be epoxied to the front flat section and the driver will be set with Artic two component epoxy to the rear flat section.

As is typical, the CU module will capture/position the LD and the Collimation lens....which will then be inserted and secured with a set screw into the non-flat machined segment of the HSOP.

So...all the goodies ride on the Heat Sink-Optical Platform insert....including the V8 driver. A short portion of the HSOP will extend out past the bezel lock ring. I wish all optics would ride within the bell...alas....this cannot be... due the separation demanded between the cylindrical lenses.

I have attached pics of the start of the project. I am waiting on DTR/Lazereer for the NUBM07E diode. I really wanted to present a build....that may also serve as a obtainable and doable design for those wanting to enter the area of Aspect Corrected Optics class. This is especially desirable in that so many of our new, high power diodes are multimode...and will benefit greatly from corrective optics !! We can hammer the beam....from a thin bar....into a box/rectangle....where width....is only slightly greater than height !!

The attached pics are self explanatory...I just removed the components where the Xenon Bulb was mounted. With these components gone, the pic shows the host open top where the +/- hook-up points are located.

The thin metal tab extending up is the negative supply for the driver and the 6mm x 6mm metal square located in the centre of the recess is the switched positive supply for the drive. Very straight forward !! Driver gets connected to these points and the LD gets connected to the driver !!

While this host was designed for two (2) standard C cell batteries...the geometry of the 25500 LiPo is exactly the same...so no modification needed for the battery portion of the host !

SO....there you have it....This project started out some time ago as the " EZ-Adaptor "....which was an add-on for just the Cylindrical optics on to any handheld. Connectivity problems with that initial design where a roadblock. The SBR is a work-around....Enjoy the build..... and stay tuned !!!:na::na:

Attachments

-

Maglite 25500 LiPo cells.jpg94.2 KB · Views: 195

Maglite 25500 LiPo cells.jpg94.2 KB · Views: 195 -

Maglite Front Bell removed.jpg91.9 KB · Views: 215

Maglite Front Bell removed.jpg91.9 KB · Views: 215 -

Maglite Heat sink and Optical platform.jpg98.9 KB · Views: 207

Maglite Heat sink and Optical platform.jpg98.9 KB · Views: 207 -

Maglite Host as received.jpg145.6 KB · Views: 214

Maglite Host as received.jpg145.6 KB · Views: 214 -

Maglite removed parts.jpg173.3 KB · Views: 226

Maglite removed parts.jpg173.3 KB · Views: 226 -

SXD-V8 4A fixed.jpg34.5 KB · Views: 211

SXD-V8 4A fixed.jpg34.5 KB · Views: 211 -

Maglite 2C As received taken apart.jpg154 KB · Views: 241

Maglite 2C As received taken apart.jpg154 KB · Views: 241 -

EZ-NUM-CL-V8 for NUBM07E .JPG128.9 KB · Views: 295

EZ-NUM-CL-V8 for NUBM07E .JPG128.9 KB · Views: 295

Last edited: