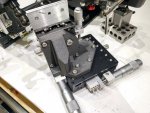

Here are the pictures of the axis. I just bought some random XY / X stages from ebay and mounted them. If you also pair it with a Noga indicator arm, you get an insane amount of freedom. You can solder anything to your hearts content with two of these.

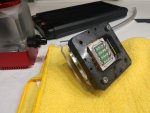

I also included the water cooling block I am working on to cool these. It is currently PLA plastic which will easily melt, but I will soon use high temp SLA resin to print the real thing once I get a design I like which will also hold the PCX lens.

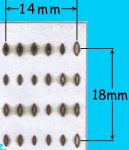

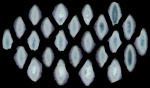

This goes back to my original question in the projector optics question in the optics thread. What exactly is the optics that they use to focus/direct all the beams onto the phosphor wheel. It would make my life soooo much easier if I could just buy the projector and reuse the special optics that they use. Although, modifying the height of the multi lens + a PCX should do the job for me very well.

I also included the water cooling block I am working on to cool these. It is currently PLA plastic which will easily melt, but I will soon use high temp SLA resin to print the real thing once I get a design I like which will also hold the PCX lens.

This goes back to my original question in the projector optics question in the optics thread. What exactly is the optics that they use to focus/direct all the beams onto the phosphor wheel. It would make my life soooo much easier if I could just buy the projector and reuse the special optics that they use. Although, modifying the height of the multi lens + a PCX should do the job for me very well.