- Joined

- Aug 25, 2007

- Messages

- 2,007

- Points

- 63

Oh yeah, and because I know some of you care, (and for teh lulz).....these diodes aren't made by Nichia.

Last edited:

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Oh yeah, and because I know some of you care, (and for teh lulz).....these diodes aren't made by Nichia.

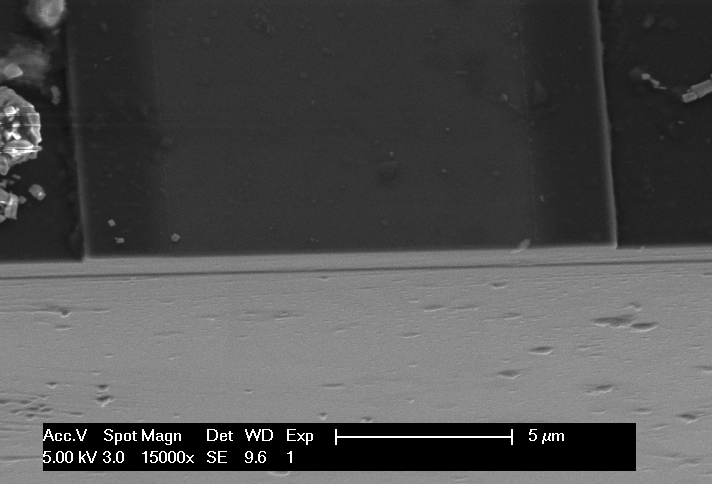

And this image is cool. It shows something interesting, and taught me something as well. Somebody guess what the horizontal black line is on the facet of the diode.

Are you talking about the 9mm or the 5.6mm ones or both.?

I had a Pretty good Idea the 5.6mm ones where Not but the 9mm ones i thought they where.

Per your Question of the Black Line Across the Facet:

The Black Line across the Facet is COD.

The line is so perfectly straight. Maybe it is an alignment mark??

Its a specularly reflecting plane.

A scratch made at the edge of the wafer and a slight bending force causes a nearly atomically perfect mirror-like cleavage plane to form and propagate in a straight line across the wafer.

And I'm very disappointed this got no response. Nothing? A black line on a high-mag sem image of the facet of a laser diode?

BTW, my inner 6-year-old was loving that. "I know something you don't know!!1!". Because let's face it, who isn't beholden to their inner 6-year-old at times."

It truly amazes me how they can pump these diodes out for such a low price.

It truly amazes me how they can pump these diodes out for such a low price.

Well, cheap for what we use them for.

You can buy a green laser for $5. Which shows they only pay ~$1.

Why's that? I don't see any reason why they wouldn't be able to.

I mean, they have automated machines that make these. The process of making silicon is relatively easy, and well sand isn't exactly a non-renewable resource considering how much sand we have.

And because it's automated I'd imagine it'd be cheap to make thousands of these...