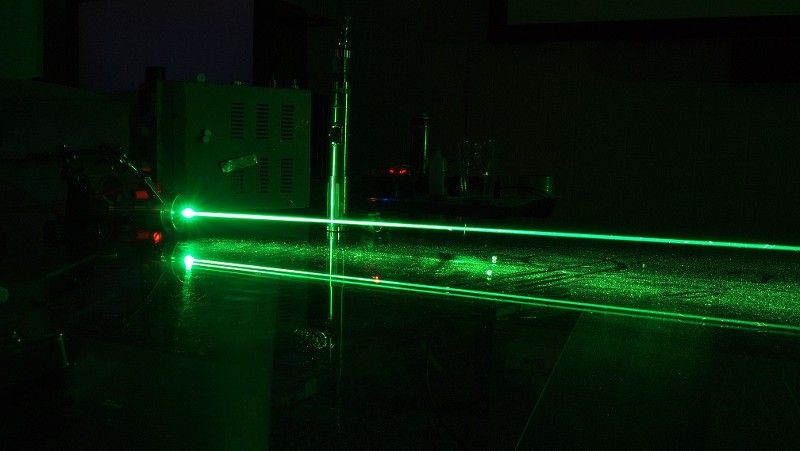

I have a question about the duty cycle, or length of time this laser can be operated without needing to shut down to allow it to cool off and then start again for the same period of time. Cooling off enough to run again

for the same period of time from a room temperature start is a key piece of information to understand it's true duty cycle at 20 C ambient.

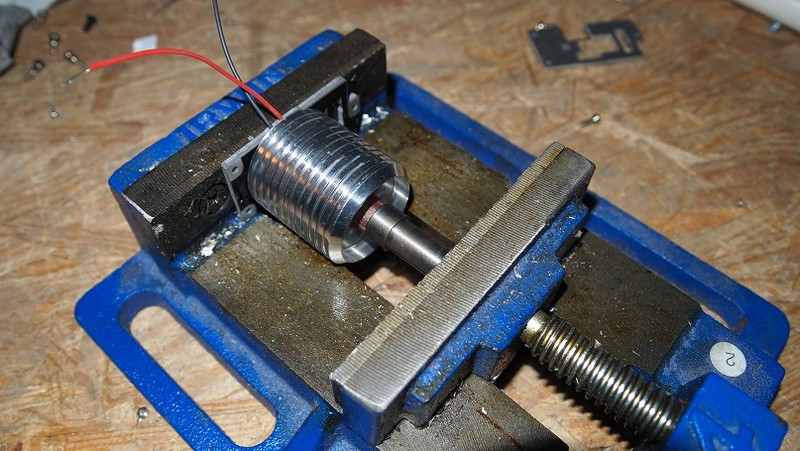

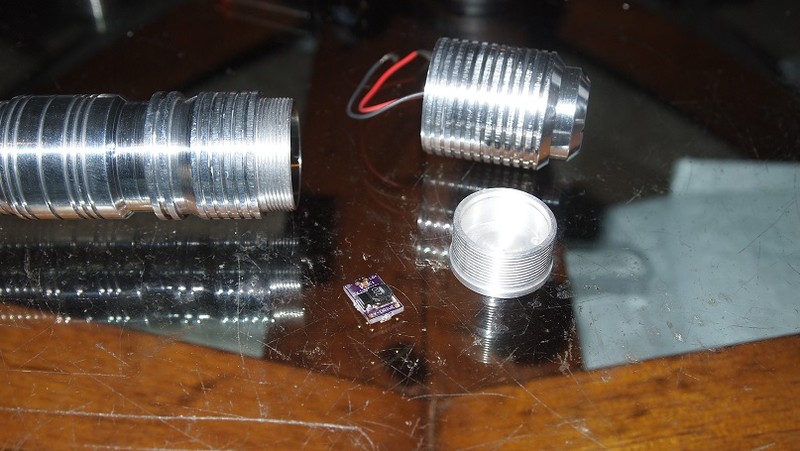

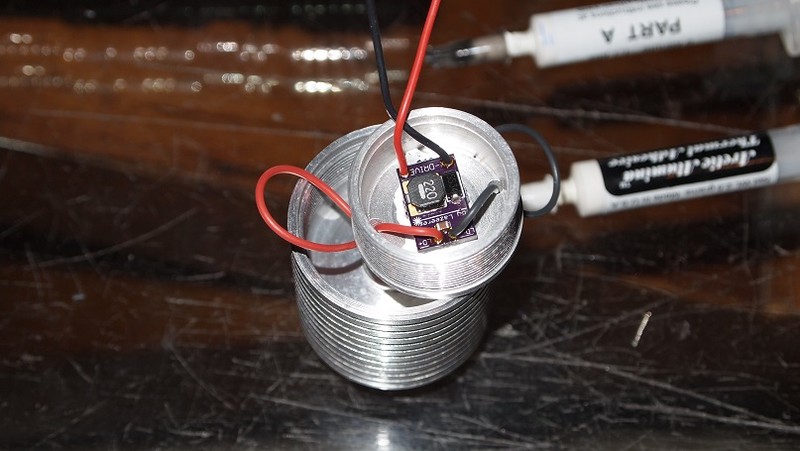

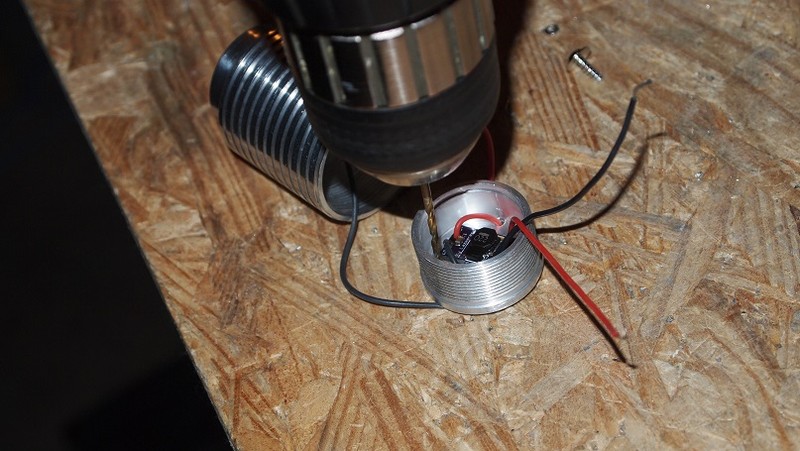

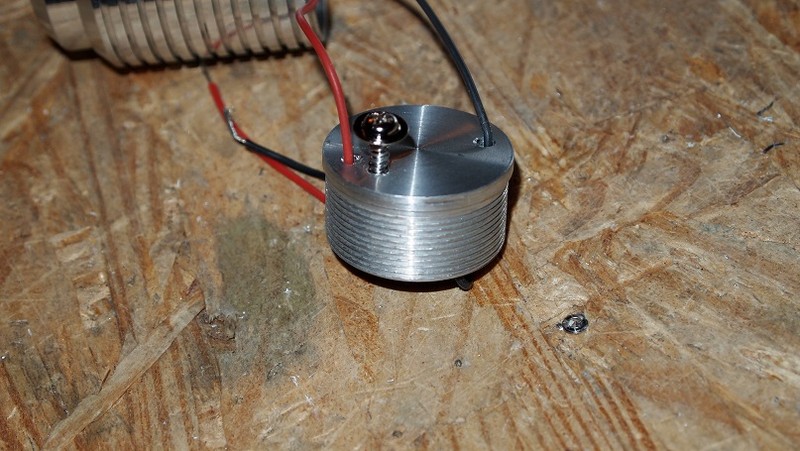

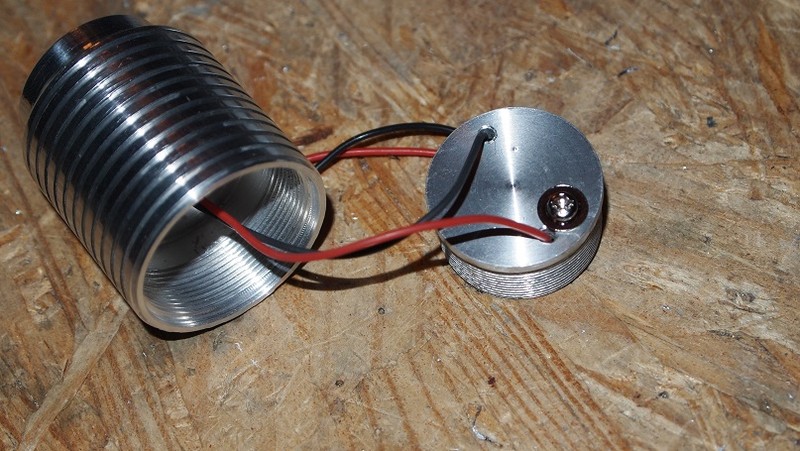

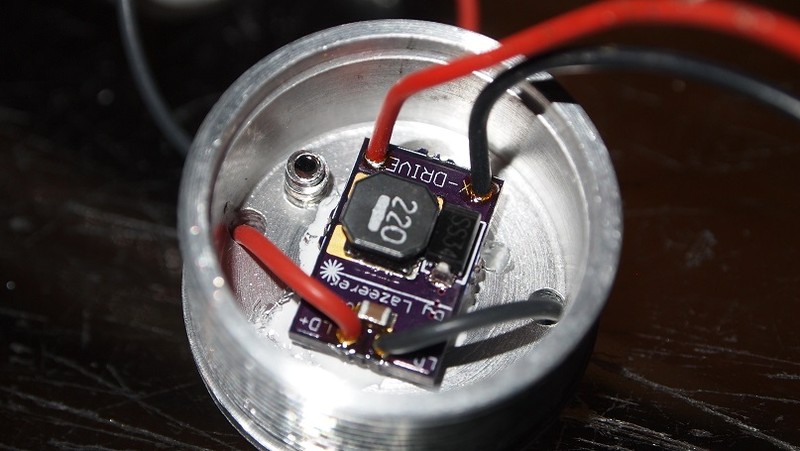

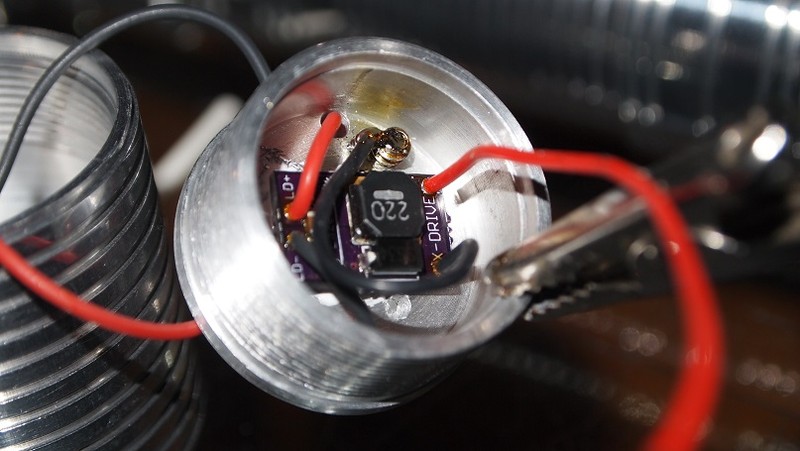

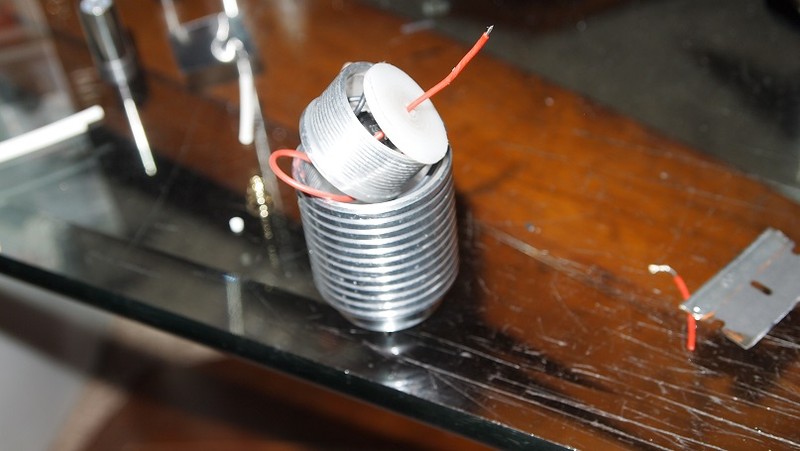

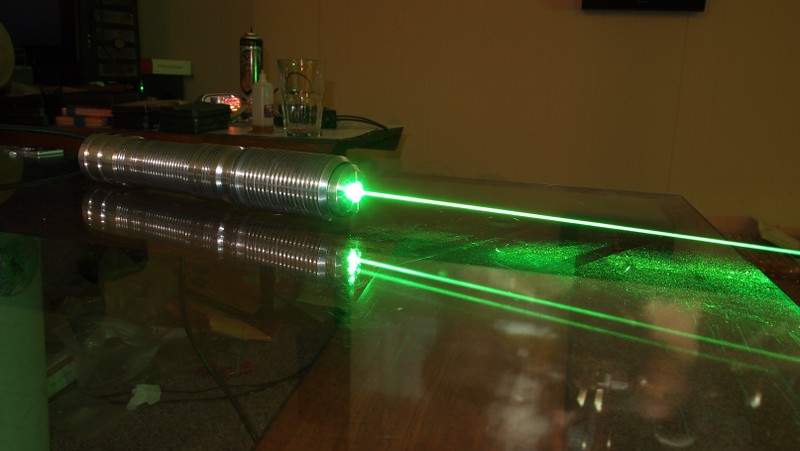

I liked the way you heat sinked your driver, but which gets too hot first to be able to continue operation, the laser diode or the driver? Maybe the heat sinking is paired up so well they are both matched for run time, in respect to heat? I want to build one of these too, but trying to decide whether to have the driver heat sinked as you did, or try to heat sink it better inside the 12mm module. I don't want the driver in mine to be the weak link for the duty cycle and so far, the only info I can find is a statement on DTR's web site the module with its internal driver can run 3 minutes, I'd like 10 minutes.

I read this thread page by page through and didn't see this info, forum searching with a few search terms didn't turn the answer up either for this specific diode and power level. When I asked DTR he referred me to the maker of the driver, and last but not least, when I did that all I received was a lonely cricket in the far distance chirping in the background

so I'm asking here

Thanks, I know this question is many months later, but isn't rising the dead, not that old of a post yet, plus this thread is worth a bump for such a beautiful awesome laser build.