- Joined

- Feb 25, 2010

- Messages

- 1,643

- Points

- 113

Well...I concluded that this LD mount deserved a separate thread !

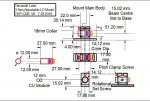

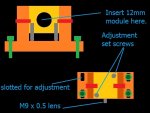

!! See attached : THP-CDB-V6 drawing.

The design was greatly inspired by Trinh H P

The design builds on previous proposed designs and has not been built yet.

A Proof of Concept will be done.

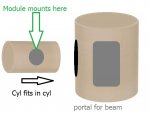

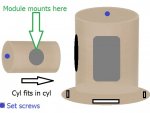

The LD mount uses two (2) rotating cylinders. A 12mm CU module w/LD....is set within an 18mm rotating collar @ 90 degree.

For Pitch adjustment, an 18mm collar is positioned within the main mount body. This collar is then positioned/rotated....up/down... to adjust to the perfect Pitch. Once the pitch is set.... a clamping bolt is tightened to fix the position and provide the best possible heat transfer between the collar and the main mount body.

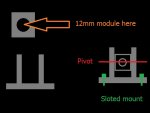

For LD Rotational alignment, the 12 mm module is positioned/rotated within the 18 mm collar unit. Once the Rotation is set...a set screw that is aligned with the 18 mm collar axis is tightened...and the rotational alignment is fixed.

Finally, for Yaw adjustment, the main mount body will be bolted to a standard Base/slotted foot plate which can be shifted left/right to achieve the best Yaw alignment. Once aligned....Fix the bolts to secure.

We have finally covered all the required degree's of movement for an LD mount...in hopefully the smallest and most simple design possible

All components will be Copper. I will machine the first unit within the next 30 days.

Thanx to all that have pushed the envelope so far !!

Drawing now attached.

CDBEAM :wave::wave::wave:

!! See attached : THP-CDB-V6 drawing.

The design was greatly inspired by Trinh H P

The design builds on previous proposed designs and has not been built yet.

A Proof of Concept will be done.

The LD mount uses two (2) rotating cylinders. A 12mm CU module w/LD....is set within an 18mm rotating collar @ 90 degree.

For Pitch adjustment, an 18mm collar is positioned within the main mount body. This collar is then positioned/rotated....up/down... to adjust to the perfect Pitch. Once the pitch is set.... a clamping bolt is tightened to fix the position and provide the best possible heat transfer between the collar and the main mount body.

For LD Rotational alignment, the 12 mm module is positioned/rotated within the 18 mm collar unit. Once the Rotation is set...a set screw that is aligned with the 18 mm collar axis is tightened...and the rotational alignment is fixed.

Finally, for Yaw adjustment, the main mount body will be bolted to a standard Base/slotted foot plate which can be shifted left/right to achieve the best Yaw alignment. Once aligned....Fix the bolts to secure.

We have finally covered all the required degree's of movement for an LD mount...in hopefully the smallest and most simple design possible

All components will be Copper. I will machine the first unit within the next 30 days.

Thanx to all that have pushed the envelope so far !!

Drawing now attached.

CDBEAM :wave::wave::wave:

Attachments

Last edited: