- Joined

- Dec 9, 2011

- Messages

- 221

- Points

- 28

HEY LOG, What is this supposed to be ?

What I posted earlier. Maybe you missed it.

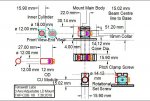

"Here is the back of a 10X P73 combiner I was just prototyping. It worked pretty good. Rotation is still a bit finicky but can be done with some patience. On the plate that holds the diode I cut a slot and drilled two holes. The slot allows me to use a small pliers to set rotation and the holes allow a small screwdriver to "push" the diode left or right. This is all the adjustment needed to align 10 diodes with 6X cyl correction. Of course there are probably a million ways to do it. This example is just one."

Basically just showing how simple it is to make a mount the allows X,Y translation of the diode and therefore correcting the angle the beam leaves the lens.

I think I might still be missing something. That is why i asked originally. But it seems people are looking to have the beam exit straight or some form of adjustment of the beam angle to allow correction and expansion after the collimator. Im trying to show/ explain the method I used to do this.

I highly doubt that a person can perform 0.001mm resolution with "bare hands" (though such precision is not needed anyway to align the relative diode-lens position). Making the diode movable in xy have to be designed in such way, that the heat transfer is still good enough for a handheld device.

Singlemode

You can. It can be done with the type mount I show. Depending on the power of the collimation lens .001 probably not necessary. With a 2mm lens I would guess ~.005mm is needed to keep the beam straight and the spot from excessive aberrations. Heat transfer is fine with copper base material. On 9mm diodes the landing can be made to have more surface area.

Keep in mind if the beam angle is multiplied by the expanders. If you start with say .5 deg off axis after a 8x cylinder set-up its 4deg of then a 3x spherical expander its 12deg off! So, initial tolerances and allignment matter here. If it didn't we wouldn't be having this conversdation:beer:

Only high-end lathes or CNC machines can reach a precision of 0.001mm, a hand is not possible

Maybe you wrong

Yes it would be very hard to machine this tolerance. That is why you move the diode manually to line things up.

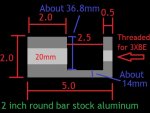

I wonder if you can get it smaller to fit the smaller diameter modules. Now that would be neat :beer:

Im sure it could be done. I have made modules with .75 inch diameter, 5.6 and 9mm diodes. Using smaller screws it could be .5 diameter.

Last edited: