- Joined

- Feb 25, 2010

- Messages

- 1,643

- Points

- 113

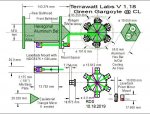

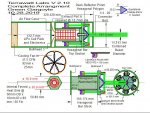

Well....BobMc....Consider that this build has six (6) LD's combined...vs the four (4) that the Blue Katar was to have.....AND....the 520nm line has about 5 X the luminosity that the 450nm line has....SWAG @ 30 X the brightness !!! Bazinga !! ….and that we are breaking new ground !!!! Hop on board !!

CDB

CDB