I used to work in a place where they did a lot of surface mount stuff.

I did diagnostics for 3D Labs graphics cards a few years ago, when they still

made things in the UK

A short while into production they decided they could get

an extra 10% speed from the geometry processor (which was a seperate chip

in those days.) by adding a resistor and a 4mm wire between a pin on a

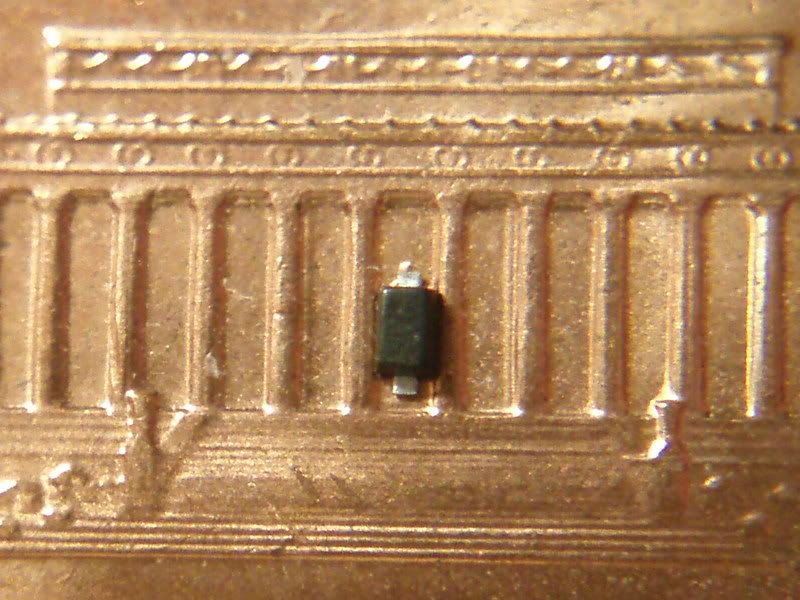

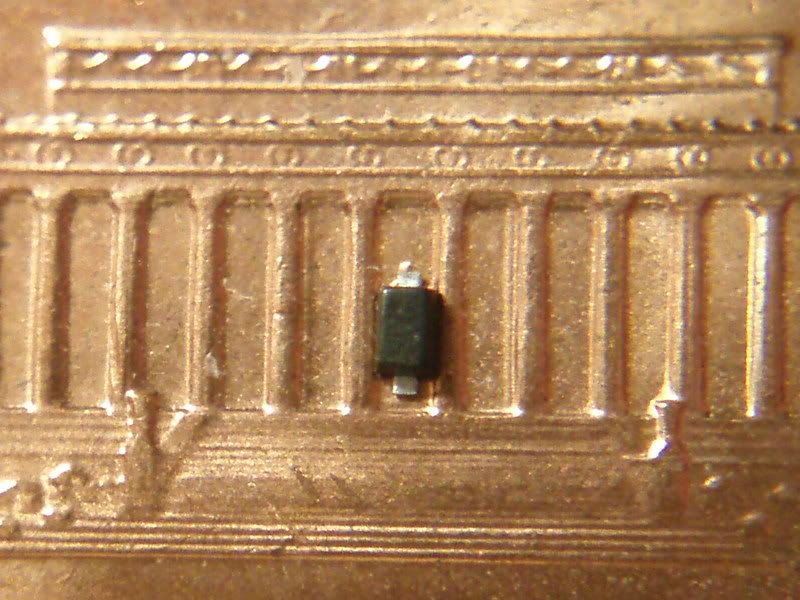

flat pack surface mount chip and a pad on the circuit board. The legs on the chip

were around 0.5mm apart and had to be soldered by hand.

I'd quite often sneeze and half a dozen resistors would fly off the workbench,

never to be seen again. :

I really enjoyed the job though. I got to play with cutting edge technology.

State of the art graphics cards that retailed for £1700 ($3390)

It helps with my laser hobby, being able to work with tiny components and

experience in soldering them + ESD precautions.

My friends still don't understand me though. When I showed them a 20x dvd laser diode

and a few beam splitter cubes and were gobsmacked when they found out to get them

I had dismantled a brand new £23 dvd writer. ;D But for them £50 on mascara is good value for money.

For me. £10 on makeup and £40 on laser parts is good value for money.