- Joined

- Sep 20, 2013

- Messages

- 20,284

- Points

- 113

Chris, by expander lens do you mean a collimator lens that is further away giving the divergence of a BE? I see you got more of these OPSL laser modules.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Very nicely done. I wasn't planning on watching your entire video, but it was so instructive I couldn't help myself. Thanks.

Heater voltage is 1.5V-2.0V. Try 3.0V at your own risk.

Not all of them have the output expander lens, mine didn't but another user on removed did have one on his.

I got 90mW - 110mW of power for different units at spec. current max (480mA, 23°C, Heater = current optimized at ~60mA).

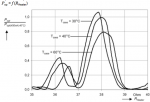

I was dubious that the heater could be controlled by setting the current for a standard amount instead of measuring the temperature and setting it that way.