IWIRE

0

- Joined

- Dec 18, 2013

- Messages

- 621

- Points

- 0

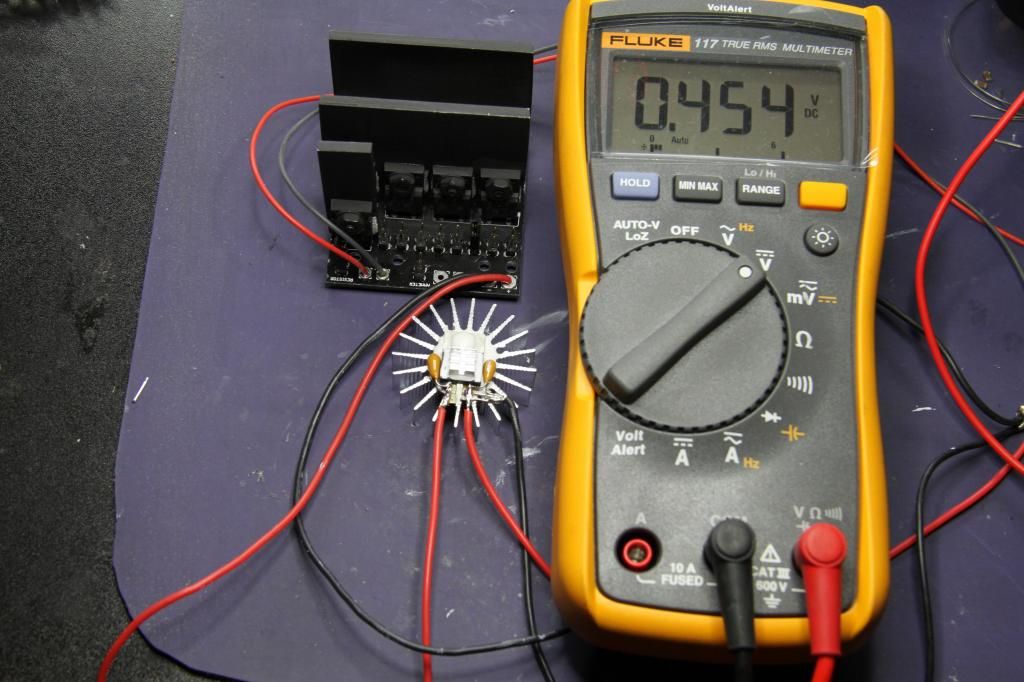

Just got a chance to test the load out. It works great ! I've been pumping 4.4a in it, I haven't tried doing it for 5 min. yet. I want to get a fan blowing across it before I try that. I'm going to look at the spec sheet for the diode, see what max temp is and shoot this thing with my IR thermometer. I have a hard time telling by touch.

I'm impressed. Looking forward to the revised model.

I'm impressed. Looking forward to the revised model.