rhd

0

- Joined

- Dec 7, 2010

- Messages

- 8,469

- Points

- 0

OSH stencils is fast. I think they cut them in the USA.

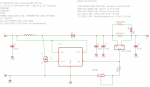

Okay, now that we have RC1 behind us, and there's a working, clean output, inexpensive 2.4A boost. It's worth discussing objectives for the future.

I would propose as a worthy next goal, the ability to reliably output a clean 4A at 5V, from a single lithium ion, without substantially increasing the size of the driver, and keeping the part costs under $10.

That's not an easy target.

Okay, now that we have RC1 behind us, and there's a working, clean output, inexpensive 2.4A boost. It's worth discussing objectives for the future.

I would propose as a worthy next goal, the ability to reliably output a clean 4A at 5V, from a single lithium ion, without substantially increasing the size of the driver, and keeping the part costs under $10.

That's not an easy target.