- Joined

- Jul 10, 2015

- Messages

- 13,094

- Points

- 113

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

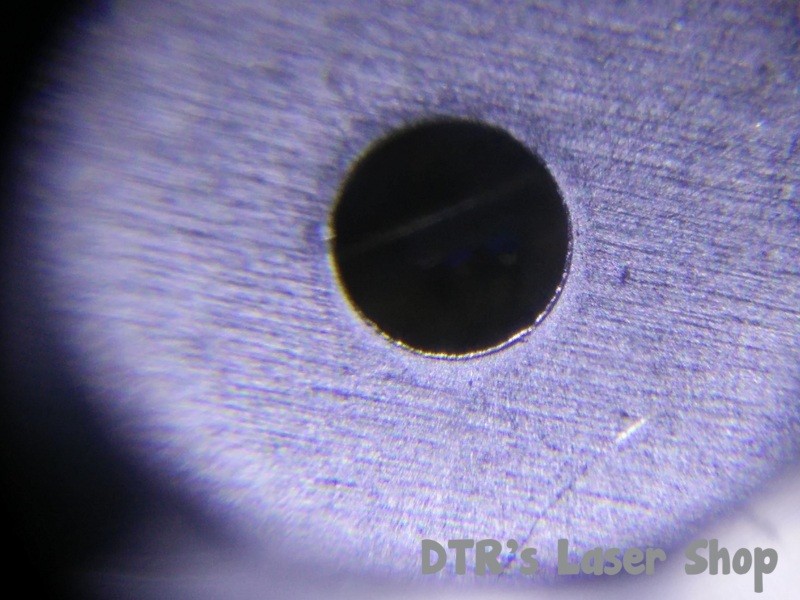

Extraction method is pretty clean. There would not be any excess dust or other particles being created due to it over other methods used for other pulls like the M140. I just checked all the ones I have extracted here and they are all spotless under my microscope. I do also power every unit including bare diodes to make sure they don't have anything obstructing the light path. Are you seeing anything in the output when you power it just to lasing threshold. That is how you can check without running the risk of burning anything on it.

Are you still using a dremel to cut away the block? Did you see my post in the vet section about heat, and did you give it any thought?

Thank you CDbeam for your contribution towards the correction of this diode. I knew the prisms weren't going to cut it. What magnification are you using for your corrective lenses? If they're 4x then would 6x be better? Could that be the key to better correction?

No dremel. Yep if the solder is heated up it will melt.

Yea that is why I have not tried a heat extraction yet.

Check out " laser blue 445 moving head lasers " on youtube if you want to see a whole diode block turned into a omnidirectional spotlight.

It is very hard to clean optics, I mean really clean them. A good rule it to never let them get dirty! If you have to, canned air is a pretty good, non-contact method, but make sure you short the leads as high velocity air (with debris) can generate a significant voltage. Use a loupe to inspect the optic and I have found a common wooden tooth pic can move or stick to a particle that I am afraid to wipe across an optical surface. A dedicated spray bottle with super pure, spectroscopic grade or at least reagent grade acetone or methanol can blast dirt off complex surfaces, avoiding the need to wipe. Methanol is safer and less aggressive toward potting compounds and adhesives.

I agree that temperature is not likely my problem, but testing another diode in two different hosts should clear that up

CD,

Where are you measuring your near field, relative to the diode face? What does the correction do to the power?

With these very divergent diodes like the P73, you can adjust the magnification ratio of your cylinder pair simply by varying the distance from the diode. As you increase this distance the first cylinder is struck by the same ray angle, but further from its axis and so becomes more powerful. Consequently the second, positive cylinder has to be spaced further from the first lens, increasing the magnification.