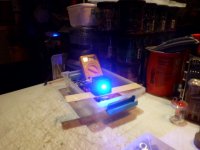

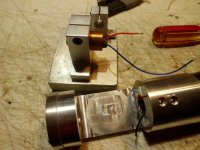

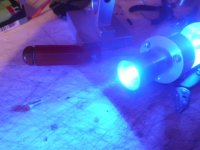

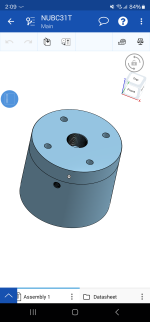

I received 2 more re-canned NUBM0F today and put them in 12mm copper modules from Barnett Unlimited with a good quality thermal compound and they both tested 8.2W @ 5A and 8.65W @ 5.5A from a cool start and using the same pair of clean new G2 lenses and testing both diodes with both lenses to prevent any errors which a dirty lens can easily cause.

I think 5A would be a good working current for quasi continuous use in limited duty cycle builds the way we do.

So far my 1st diode is the strongest but not by all that much more.

p.s. I did push to 5.9A from a cool start but could not break into the 9's like my 1st diode did @ 5.7A, however these 2 are close and good for 8W+ as we overdrive them ( limited duty cycles ).