WannaBurn said:

[quote author=leukoplast link=1206947255/544#551 date=1239354442][quote author=WannaBurn link=1206947255/544#548 date=1239346326]You could try shaving down the edges with a dremel for the size, and possibly relocating the input wires?

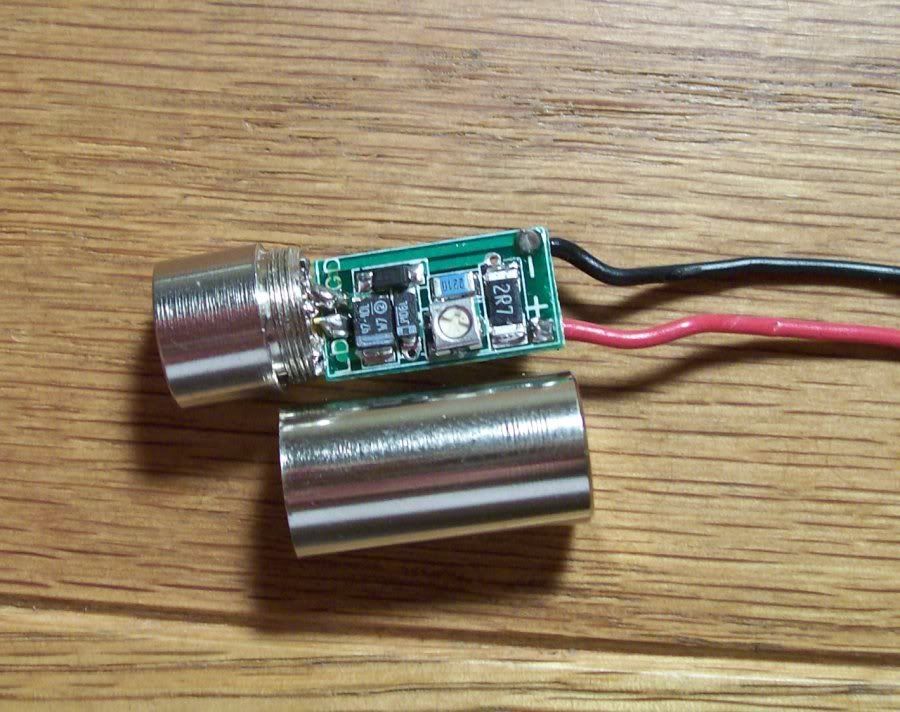

When you solder the LD to the driver, start with only one pad having any solder on it. Get the LD positioned and perfectly centered. Once you are happy with the placement of the driver in relation to the LD, proceed with soldering the other pin to pad. Dont solder the second pad until you are ready to commit.

When soldering any board to the back of an LD, the slightest shift off center can really play havoc on getting that rear cap on.. This could be part of the trouble your experiancing.

Keep a can of paste near by, keep your iron tinned and solder as quickly as possible.

I havent personally used these drivers, but many other members have fit them in. So its possible, though it does look trickey.

Is the rear cap absolutely needed for what you are doing? If not, it may save you some frustration to keep it out of the equation

Thanks for the tips.

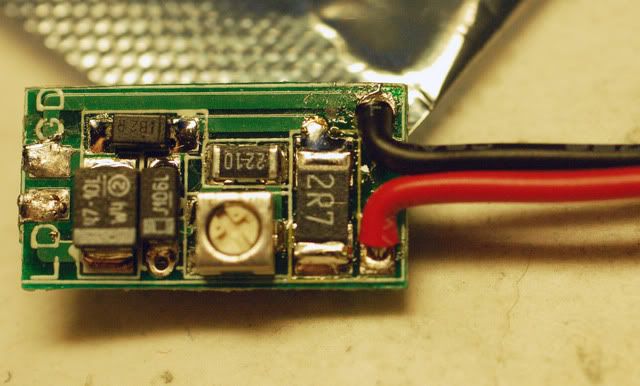

And yeah, one of the issues was aligning the pins to the pads, they are so small and my eyes just aren't that good. I have the helping hands thing with the magnifying glass, but most of the time it just gets in the way and doesn't work so well. So its hard for me to tell if the pins are flat on the pads or not. Plus, the soldering iron I am using, while a pencil point, is still pretty big for this tiny job. I am sure most everybody uses the same thing so either I am really bad at this, or somehow the laws of physics are against me. But the point of the iron just takes up so much room, half the time when I put it on there I cannot even see what I am soldering. I dunno if there is any smaller tips, but one half the size would work wonders for me.

Also, do you guys normally tin the diode pins?

And I suppose I really don't need to have the back casing on, but it would help hide my shoddy work and plus give the driver+diode pins some extra protection from being bent or any ESD related type stuff. [/quote]

No problem

Another thing I forgot to mention is...

When soldering with short LD pins, you must be careful not touch anything other than the pins on the LD and pads. I still do this from time to time when tired, where the irons tip is touching the back of the module and delivering some nasty heat

You mentioned that the whole head was really hot in your practice run, and its hard to tell by the pic, but it looks like their might be some solder on the axiz module..

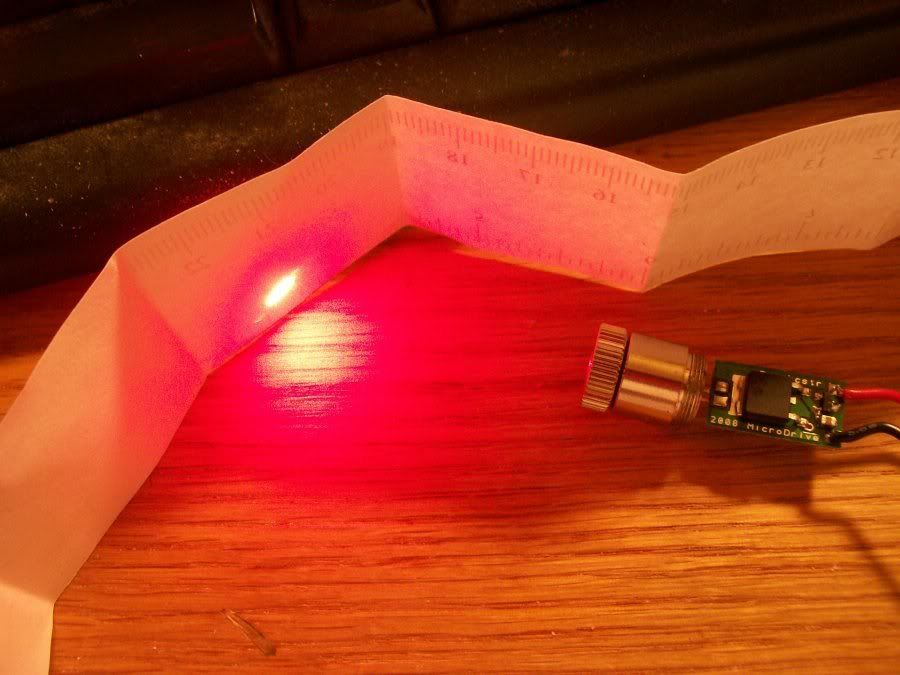

A good trick for this is to keep your pinky finger on the module, if the iron passes too much heat, you get a nice little warning

Also some people like to solder at a low temperature.. I solder at 800 deg, basically double the temp needed, but it enables me to solder twice as fast. The parts never even get warm this way, only the joints see the temp. You may want to try this with a practice run and see if it helps.[/quote]

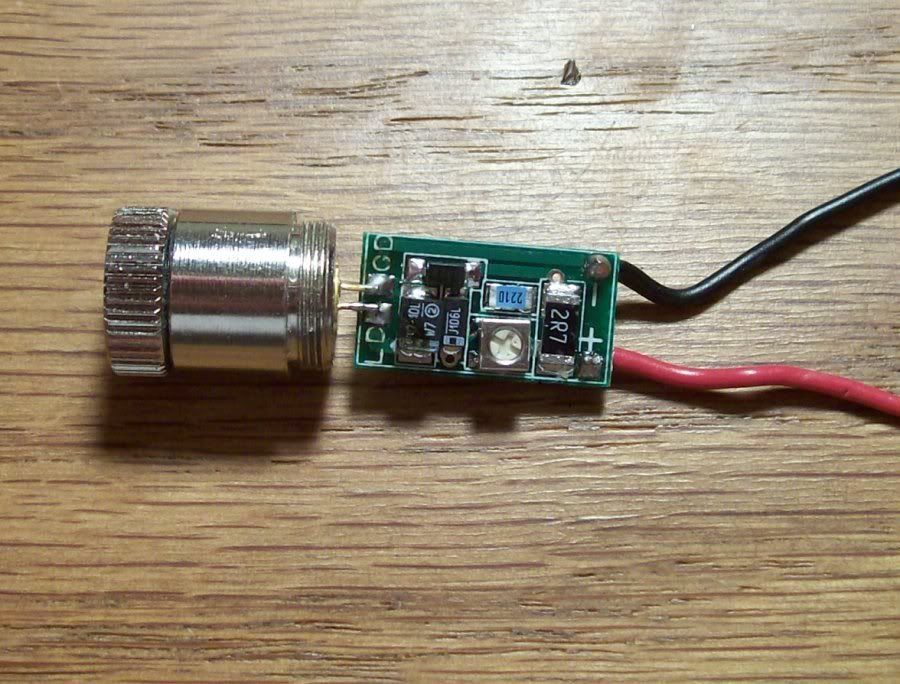

rkcstr, thanks, that is a good visual for me to work with, I think I can do that.

Wannaburn, yeah, the problem is the amount of space between the module and the pins on the driver, which is pretty much exactly the same size as the iron tip, so moving one way or another in any direction will either heat up the module badly, or start frying and melting the driver pins. And this is almost impossible for me since the tip of the iron still has to be angled a certain way to hit the right spot.

Also, I have a Weller fixed temp iron, it does 750 degrees.