- Joined

- Jun 24, 2010

- Messages

- 5,705

- Points

- 113

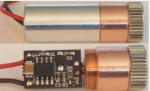

Re: New 9mm 445 diodes

Just want to make this clear as I got a PM from brunes01 thinking his driver would become damaged if he did not sink it.

The X-drive in these modules have been shown to be capable of a good 60-90 second duty cycle on two cells with no heatsinking at all. If you use three cells you will want to sink it as that would decrease the duty cycle dramatically and most hosts that take 3X18650's have plenty of room to find a good place to sink the driver.

The X-drive employs a very solid thermal protection system if your run them longer than 90 seconds without heatsinking which prevents any possible damage to the driver and I have certainly not seen any longevity issues with this driver.

Heatsinking the driver will extend out that duty cycle but in an 18650 sized host like the one he is looking at I usually suggest to stick to about a 60 second max duty cycle for the sake of the diode anyway so that would be the bottleneck as apposed to the driver.

I have been selling them like this for quite some time and have yet to see a driver die or get damaged from heat or even pretty much anything else except reverse polarity. These things are tanks compared to other driver I have used in the past and I really have not had any reports of customers being unsatisfied with the drivers duty cycle on the unit as it comes.

With that said I would if you can with the setup you have sink the driver to the host body and you feel capable doing it that is a great idea but from what I have seen there is no dangers to your driver if you do not.:beer:

Just want to make this clear as I got a PM from brunes01 thinking his driver would become damaged if he did not sink it.

The X-drive in these modules have been shown to be capable of a good 60-90 second duty cycle on two cells with no heatsinking at all. If you use three cells you will want to sink it as that would decrease the duty cycle dramatically and most hosts that take 3X18650's have plenty of room to find a good place to sink the driver.

The X-drive employs a very solid thermal protection system if your run them longer than 90 seconds without heatsinking which prevents any possible damage to the driver and I have certainly not seen any longevity issues with this driver.

Heatsinking the driver will extend out that duty cycle but in an 18650 sized host like the one he is looking at I usually suggest to stick to about a 60 second max duty cycle for the sake of the diode anyway so that would be the bottleneck as apposed to the driver.

I have been selling them like this for quite some time and have yet to see a driver die or get damaged from heat or even pretty much anything else except reverse polarity. These things are tanks compared to other driver I have used in the past and I really have not had any reports of customers being unsatisfied with the drivers duty cycle on the unit as it comes.

With that said I would if you can with the setup you have sink the driver to the host body and you feel capable doing it that is a great idea but from what I have seen there is no dangers to your driver if you do not.:beer: