Thank you Jarrod.

Nice pics! But how do you wanna make a tube from scratch? Quarz-glass for the inner tube and plexi for the outer tube?

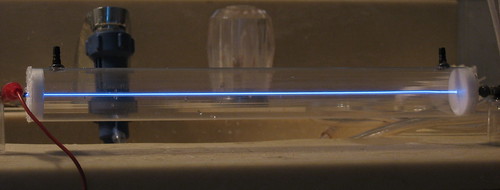

Well - I'm been experimenting with different setups. My first setup used a cold cathode fluorescent lamp tube from inside a flat screen monitor, with a clear polycarbonate tube lamp guard for the water jacket.

However, I decided to discontinue it. The tube was only 1 or 2 mm ID, and it was too hard to manage in this form. Alignment would have been far too difficult, keeping the tube perfectly straight was a problem, and the hole through which the beam would pass would have to have been too small.

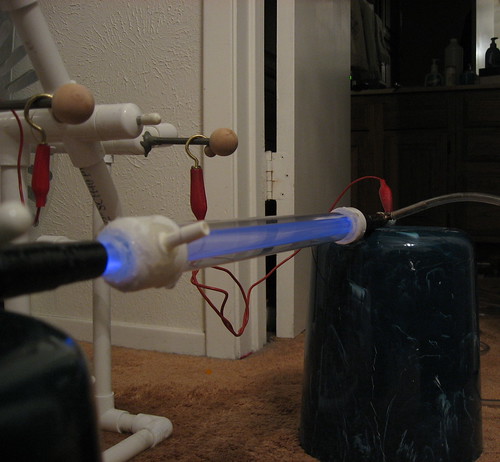

Next, I started working with this larger design:

That one was made out of 2 fluorescent lamp tubes. One tube was narrower than the other one. The wider one was placed around the narrower one, and was terminated at it's ends with PVC end caps. The narrower one extended out past the ends of the wider one, and was terminated by copper electrodes. The wider tube was used to serve as the water jacket. Here is a better view:

Last night, however, I accidently broke this tube :yabbem:

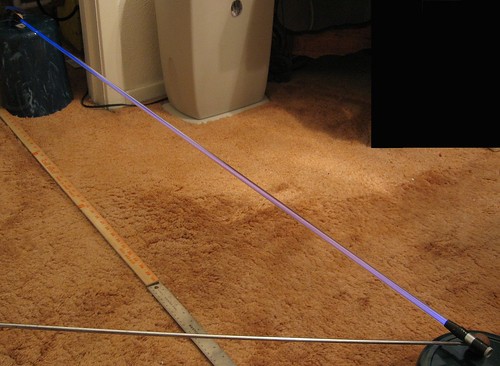

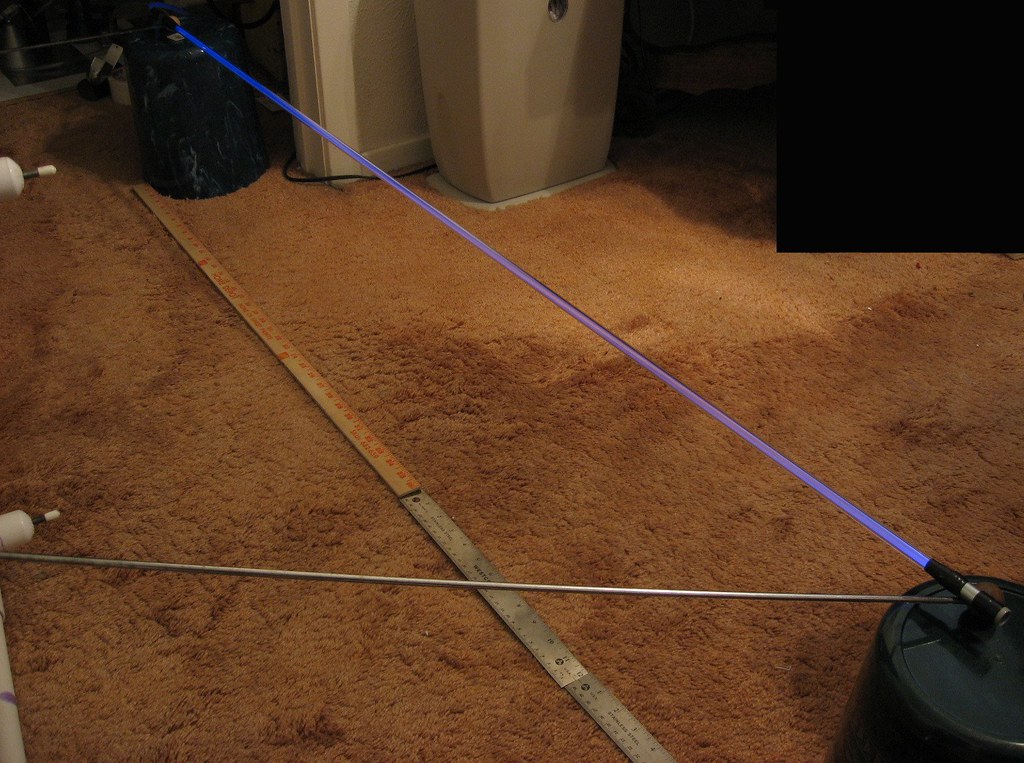

So now I am beginning once again with a new design. This time I am experimenting with longer tubes. Here is another low pressure air discharge (which is what all of the previous pictures show) in a 5 foot long tube!

So my next design will use a longer tube, although shorter than the one shown in the picture above. I hope this time I can complete it without messing something else up :yh:

Would be a flowing-gas laser-tube right?

Basically, yes. But I would like to flow it slowly, or as little as possible if I can get away with it. I can't afford to 'burn' gas.

A TEA CO2 laser would be kinda cool!