Uhm, sorry, but i think this must be said, also if it can blow some dreams

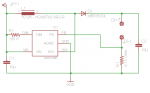

When reading datasheets and designing switching mode drivers, there are some facts that must be kept in consideration .....

First, when you read "Switching current 2.1A", it does NOT mean that the driver can do 2.1A ..... that is only the INTERNAL switching current ..... and, indicatively, for buck drivers, the maximum safe current that you can obtain is half of this current, where instead for boost/sepic drivers, the maximum safe current is usually 1/3 of this value (i said "safe" current intentionally ..... overdriving the chip you can reach some more current, also 2/3 for buck and half for boost, but this stress a lot the chip, putting it in a non-safe working condition ..... this can end in a failure, and if this is acceptable for a LED, is not so much happy when it happen with your high-cost new LD connected

)

Same is for the inductor saturation current, that must be choosen usually AT LEAST the double of the expected output current, sometimes also 3 times higher.

As example ..... i got one prototypes with LM3410X that reached 1.2A and worked for long time (heating a lot, heatsinked, and using a 10uH 4A coil), but also burned another one with the same current ..... the normal output current for a LM3410 chip used as boost/sepic driver, is around 800 / 900mA, and this chip is marked as "2.8A" switching current ..... it can be increased a little, using larger output capacitors, but then the driver becomes "a bit too big"