celas

0

- Joined

- Feb 13, 2015

- Messages

- 76

- Points

- 8

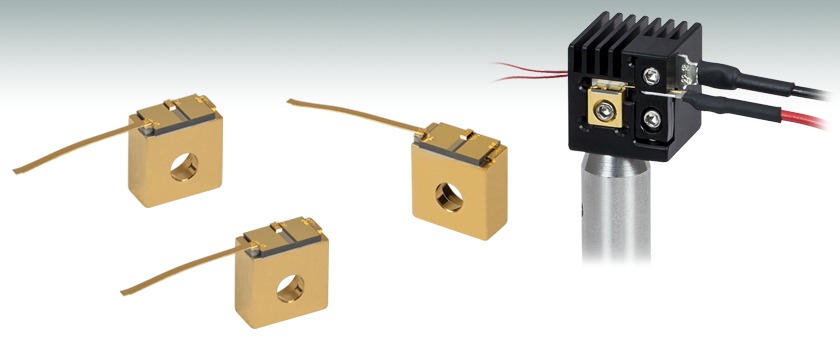

What is the best way to attach a broken negative lead in C-mount diodes?

Careful soldering or some kind of conductive glue? I accidentally broke of negative lead from high power 808nm IR pump and I need to get it working again. What are your methods of dealing with this kind of situation?

Careful soldering or some kind of conductive glue? I accidentally broke of negative lead from high power 808nm IR pump and I need to get it working again. What are your methods of dealing with this kind of situation?