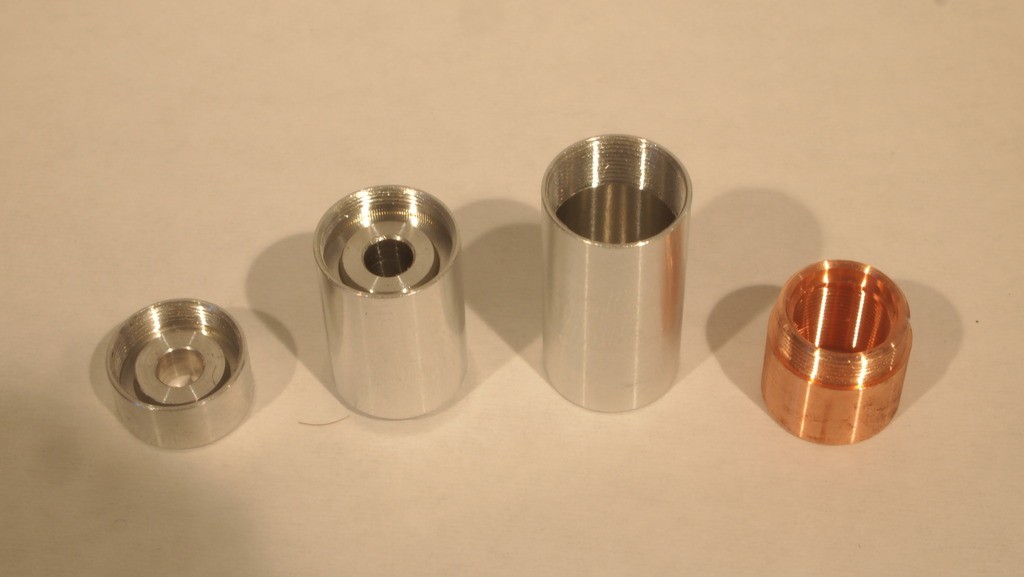

That is why I have two sizes for the 9mm thermal back half. The larger slug style one for regular 12mm set screw hosts and the shorter one for some of the new direct press hosts like the sinner ones. It will be hard to press a sold 18mm piece into a sinner head or similar direct press host along with the module in front of it. Trust me I tried and broke my vice

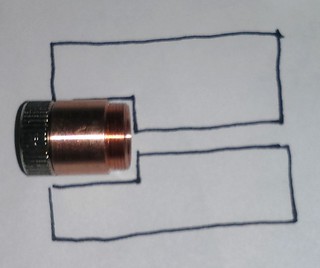

All my 9mm diodes in modules come with the larger thermal back half slug standard except those with drivers which the hollow aluminum back half which works to fill in the thread gaps. If you need the shorter back half you can request it and I will use them instead of the longer one. Also if you want the large slug back half and the driver separated by leads to sink to your host body that is available as well by request.:beer:

You will be hard pressed to find any performance difference with this particular part being copper vs aluminum but for the copper lovers I have some in copper coming as well.