Ra1nfade

0

- Joined

- Jan 27, 2011

- Messages

- 701

- Points

- 0

Yeah I wouldnt expect that for awhile IF copper is even needed for these chunky sinks. I'm probably going to wait for the direct press aluminum for a 12X build with a 501B

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

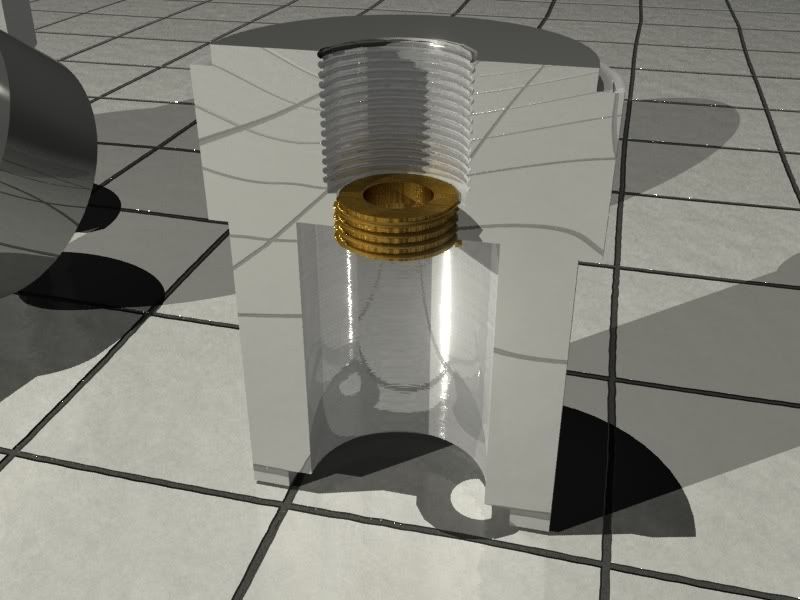

You'd first solder the wires, and then press it in. It should not be a problem.

My new personal 445nm will use this particular heatsink, just for proof of concept.

In the last resort, I can always make the heatsink in two parts, the body detached from the collar where all the components are. But it should not be neccessary.

What, like the back of an Aixiz housing?Would you then need a special diode press where you can feed the wires through the center of it?

Yeah eudaimonium, have a heart for the linear driver DIYers and people who can't seem to getjakeGT said:a 2x18650 one would be INCREDIBLE too!!