- Joined

- Feb 5, 2008

- Messages

- 6,252

- Points

- 83

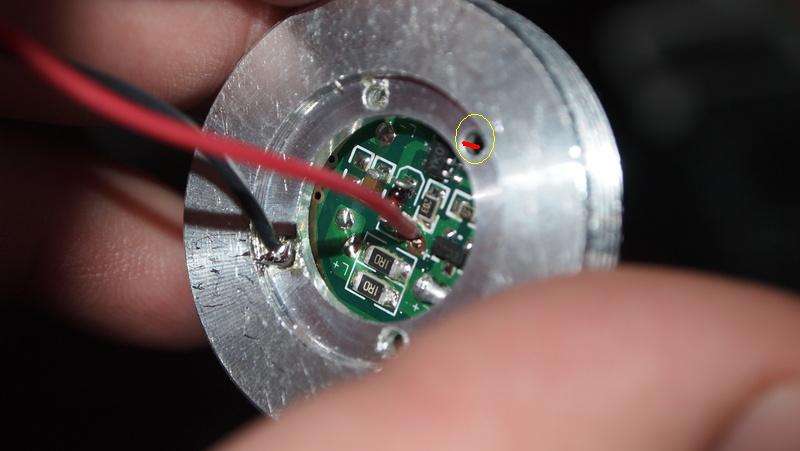

Uhh wait a minute, I don't get it now how exactly did you connect that wire to the host?It is hard to see but it is actually connected to the thick unshielded negative wire that used to come up through that hole. I did cut it a little short and next time I will leave it sticking out a little. It would pop right off aluminum if I tried to solder to it. I will always prefer to get the negative feed from the host so it has less distance to travel but some hosts make this difficult.

The current draw is actually over 3A from the battery.:eg:

Also, distance the current travels matters if it's meters we're talking about... but centimeters? :undecided:

I prefer the secure and permanent connection via case pin of the diode, after all that's what it was meant to do anyway.

Your wire would pop right off because solder did not "wet" the surface of the aluminum, to get it to do that, you need to heat up the surface you're soldering to the soldering temperature. Since it's made of aluminium, it means you have to heat ALL of it up to the solder temperature.

And that's one more reason to use the case pin.

Just a heads up.

Great build, by the way. You have a thing for 2-pound heatsinks.

Make one huge-a$$ monstruosity like that with a copper heatsink! Hah! It'll replace the gym completely!