No poblem things happen. I actually was just looking at the pic you sent over on ebay and maybe I just cant see as the pics are not that clear but the case pin should be visible on the bottom side or the nub if you had clipped it off so if it is not where the arrow is in this photo but on the other side(assuming it is a M140) then that would be backwards.

Let me know if I am seeing that right or just not getting a clear view.

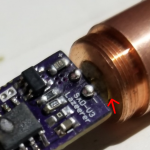

Another note the diode looks to have had a bad press or there is just an issue with the module as I think I can see the lip of the diode.

Could just be the module depth is not right, a mispress and either slightly crooked or deformed the edge of the diodes base, some material scraped down the wall the base was being pressed into and not seating fully.

Probably not going to be something to get too worried about just noting what I see on these modules and with a lot of modules going around now I have seen some big difference in quality as well as something that I think is highly contributing to death of the diodes with the integrated lenses that get removed.

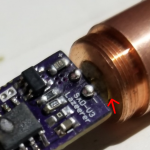

I can see the grade of the copper is lower and the machining looks to be poor. The easy ways to spot are the surface is not as smooth which is due to impurities mostly but bad machining also compounds the issue. The density is not consistent which give it that surface and color but the biggest issue is the bits and pieces from the threads. You can see waviness in the threads from bits of the copper falling off which more and more everything you thread a back or lens in meaning debris in the diode pocket. They tend to machining them very loose as lenses can bind easy if tight since they are digging though material as they go. Then you get copper for the thermal abilities which with poor tolerances, that rough surface and the impurities itself can all compromise the ability of it to move heat at all.

Anyway that is my rant for the day.