After you seat your fiber cable into the termination and crimp/secure it you score the glass fiber itself at the end of the termination and pull it away from the termination to break it as clean as possible at the end of the termination center stalk that countersinks into the ThorLabs lens end so you don't have to do a bunch of alignment.

Now after you score the fiber and pull it to break it clean you must polish it flat and clear, the face of the fiber should end up being perpendicular to that center pin that it's seated into. This is why they polish with the disc and flat plate under the abrasive, to be sure the polished face of the fiber is perpendicular to the termination stalk it's seated into.

If you feel there's any unevenness where it broke you can use a slightly coarse grit to get it flat then polish with the super fine and then ultra fine.

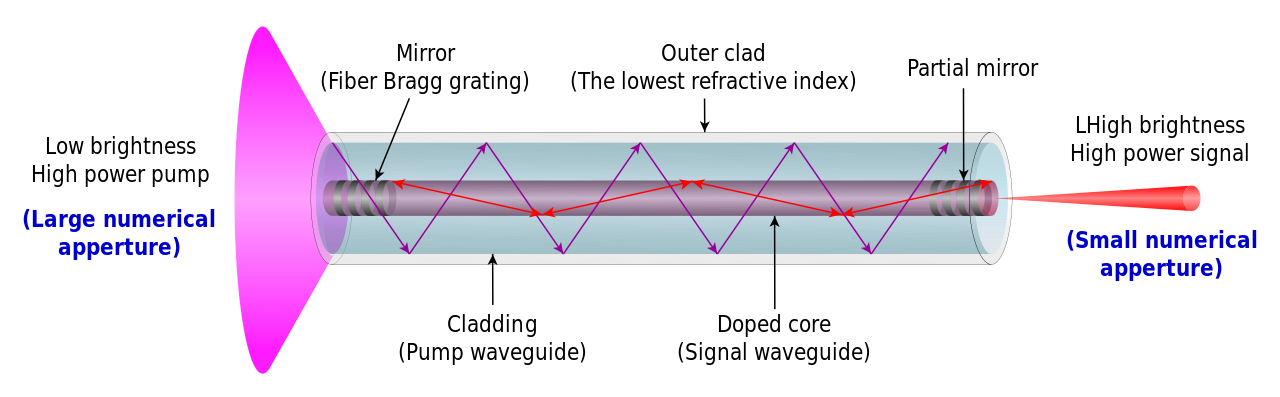

The termination should countersink into the lens ends ThorLabs sells, the grin lens if needed helps to collimate across any free space between the fiber and the lens. Ask ThorLabs what you need, tell them your multi mode fiber core dia. cladding dia. and wavelength.

I have not yet done this myself, I just bought a NV camera that doesn't have that IR blocking filter so I can set it up and work without having to hold a modified hand camera, I will be wearing attenuation safety glasses that absorb stray/diffuse and hopefully not any specular reflections while working with IR so that I can see the beam/spot on my monitor.

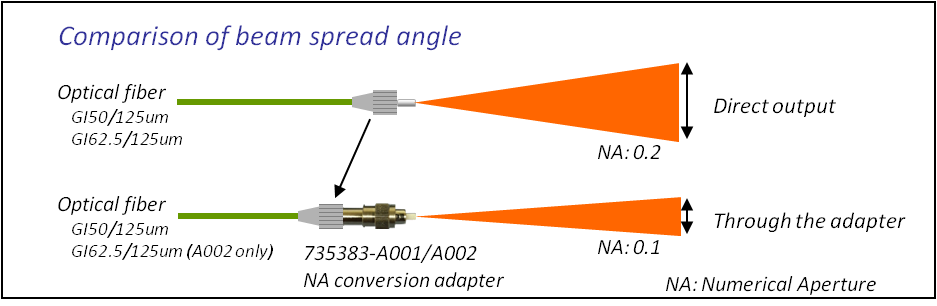

So what I am saying is the IR light coming out of your polished fiber will diverge based on the numerical aperture that's determined by your multi mode fibers core and cladding diameters and it will diverge pretty aggressively, so because you may have some small space between your fiber's polished end and lens of the adaptor you may need a gradient index lens that will collimate your beam and let it traverse any free space before your focusing lens, just what lens you will need I don't know, but Thorlabs can tell you based on your core diameter, cladding diameter and wavelength.

You may want an adjustable telescope end to expand and focus your beam or you may want a fixed lens for CNC.

Here's an example of installing a termination, you can see how he scores the extra fiber and polishes it flat with the disc.

Here's a different type of termination, but it works the same, see how he scores the glass and polishes it.

**Please note: The information I share is to the best of my knowledge correct, but although I intend to in the future I have not as yet done this procedure, I can see that you will want the correct termination for your fiber, so talk to ThorLabs and get the right termination and adaptor/lens that you need.