The end of the fiber is jagged, my cleaver should be here soon and I will get some pics after cleaving it and see how it looks.

Yea, I may just use a 60w TEC with a finned sink on the hot side, then a copper plate on the cold side between it and the laser module and power it on to buy some additional runtime between cooling down periods, a bit of pre chill may help but I wouldn't get it cold, maybe just 60F or so and see how fast it warms up, I will no doubt do some testing before the finish build, heck I hope the beam quality is decent, if so I may build something interesting with several of these.

That said the active fiber I found is really expensive, but I know they put several pumps onto a single fiber before the active fiber, so just combining three or six 25w pumps could be fun, I have seen fiber jumpers that combine 2 into 1 that are affordable, as in under 200 dollars IIRC.

I saw Dash apple had some other cool videos, seems like most of us brothers of the light also enjoy high voltage, LOL

Dash do you use any active cooling or just a heat sink on your 974 ?

----------------------------------------------------------------------------------------------------------

Ok I received my 18 dollar fiber cleaver and here is what the cleaved fiber end looks like, much better but still rough.

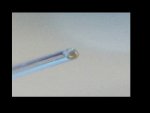

Then I picked out a clothes pin with a good looking flat edge and placed the fiber end just barley protruding from the clothespin edge and with the sand paper on top of a flat aluminum block I gave it a 10 second polish with the 600 grit then 10 seconds with super fine paper and wow did it clean up the face of the fiber, next a quick power up video clamped to a block of copper to see what it will do without a lens, safety glasses will be worn.

Also I cleaned the fiber before and after with an alcohol microfiber pad, the kind that come 100 to a box in foil packs.

AFTER POLISHING