- Joined

- Feb 12, 2016

- Messages

- 589

- Points

- 63

Hi Bob aka CDBEAM,

Sorry, many months I did not have much time for posting.

How is your project going?

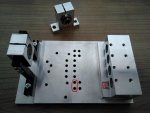

I made a new bigger baseplate somewhat similar to you drawing but for combining, not for KE.

Here all 4 beams can be expanded before PBS, WP and dichro and also a Sanwu BE could be adjusted at the end (I hope hole positions are right).

As you can see the positioner was made from SK16 with hole expanded to 17.5mm (to accept Sanwu adapter) in L-brackets from Stanwax.

All was done by CNC shop here in Spain which jors has recommended to me. If it works we could start mass production one day...

Now they do another piece for KE, I will show it when ready.

Sorry, many months I did not have much time for posting.

How is your project going?

I made a new bigger baseplate somewhat similar to you drawing but for combining, not for KE.

Here all 4 beams can be expanded before PBS, WP and dichro and also a Sanwu BE could be adjusted at the end (I hope hole positions are right).

As you can see the positioner was made from SK16 with hole expanded to 17.5mm (to accept Sanwu adapter) in L-brackets from Stanwax.

All was done by CNC shop here in Spain which jors has recommended to me. If it works we could start mass production one day...

Now they do another piece for KE, I will show it when ready.

Attachments

Last edited: