- Joined

- Aug 25, 2010

- Messages

- 533

- Points

- 63

This was really an endless nightmare, a neverending story.

After 18 waiting months and the same budget spent for an Hercules 600, I have finally in my hand a c-mount red laser with the new Lazereer ramp-up driver.

I prefer to avoid to list all the problems and issues that I have encountered, also because no one would ever believe a similar compilation of misfortunes.

The name "Jayzereer" was an invention of mine, in honor of the big work done by Jayrob and Lazereer.

So, the host has a massive 1085 grams weight (with cells), it uses 2x32650 6000 mAh Li-On black quality cells, it is rock solid, eye-catching and come with a generous aluminum heatsink.

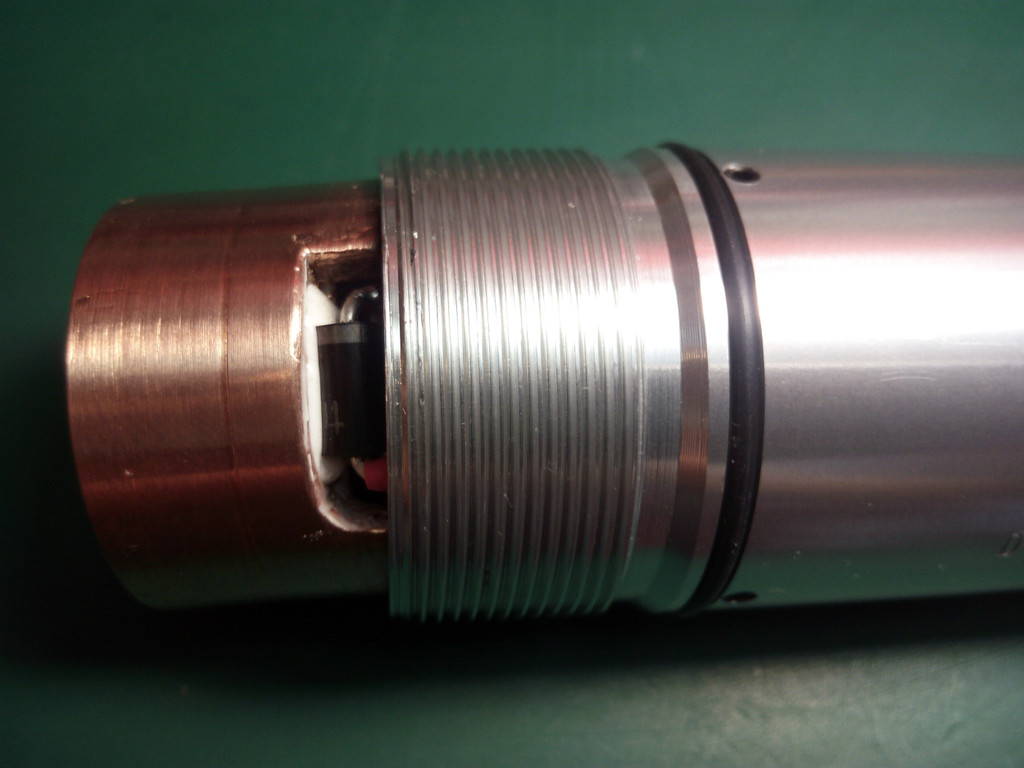

The whole heatsink contain also the lens, and it is spinning, so to obtain the required focus it's enough to rotate the whole heatsink. This was a very good idea by Jayrob!

Here are some nice shots:

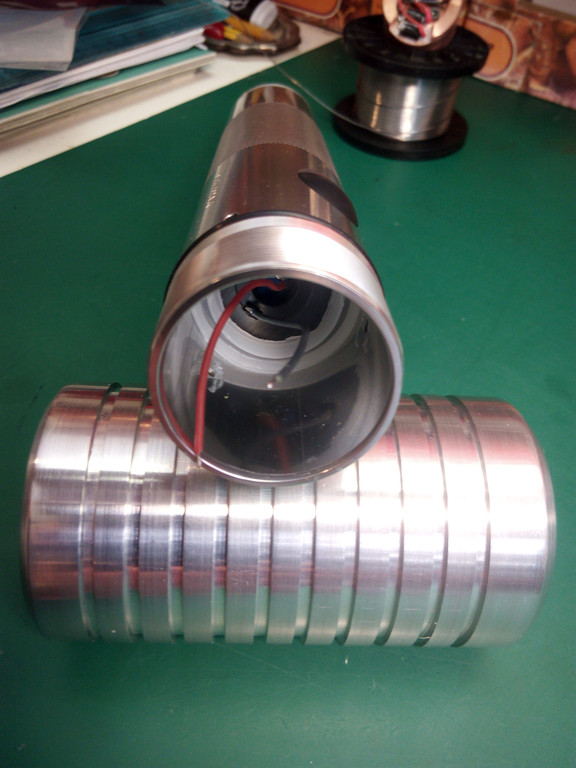

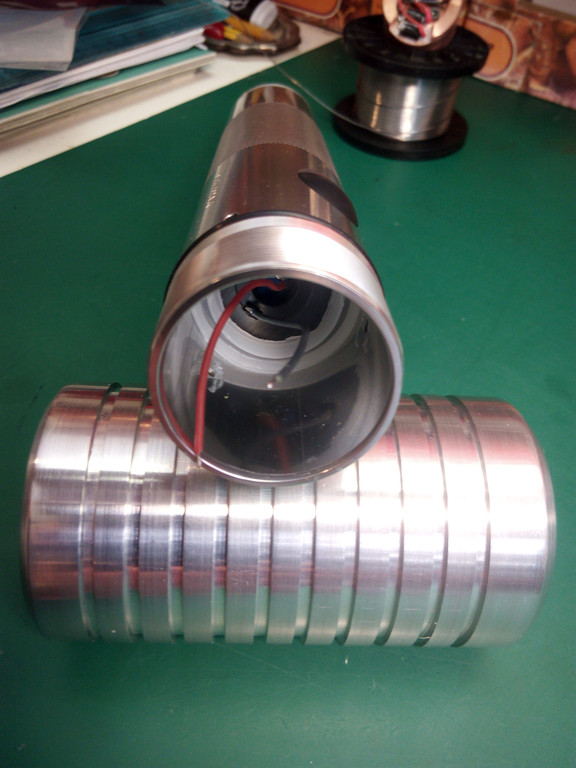

The host fully assembled:

(full resolution pic here: http://imageshack.com/a/img633/16/IaUGfD.jpg)

The headsink (head plus heatsink LOL):

The long-focus lens inside the head:

Inside the host:

The host and the original tailcap:

The modded tailcap:

(the modify was needed because there was too much spring pressure against the cells)

The cells:

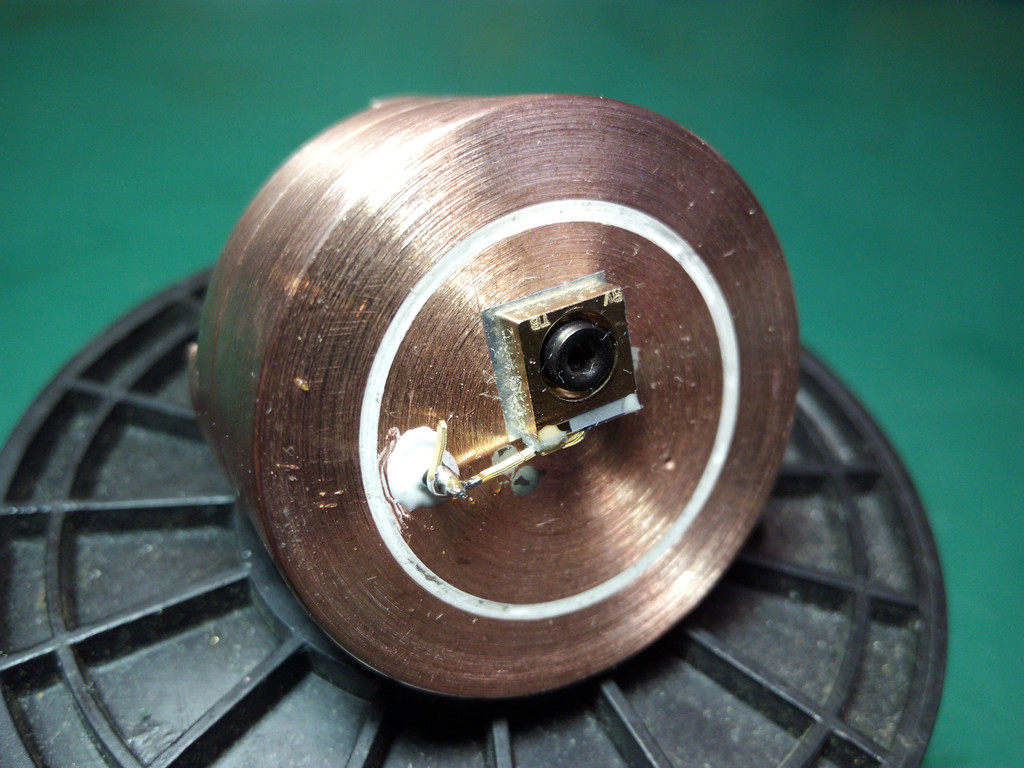

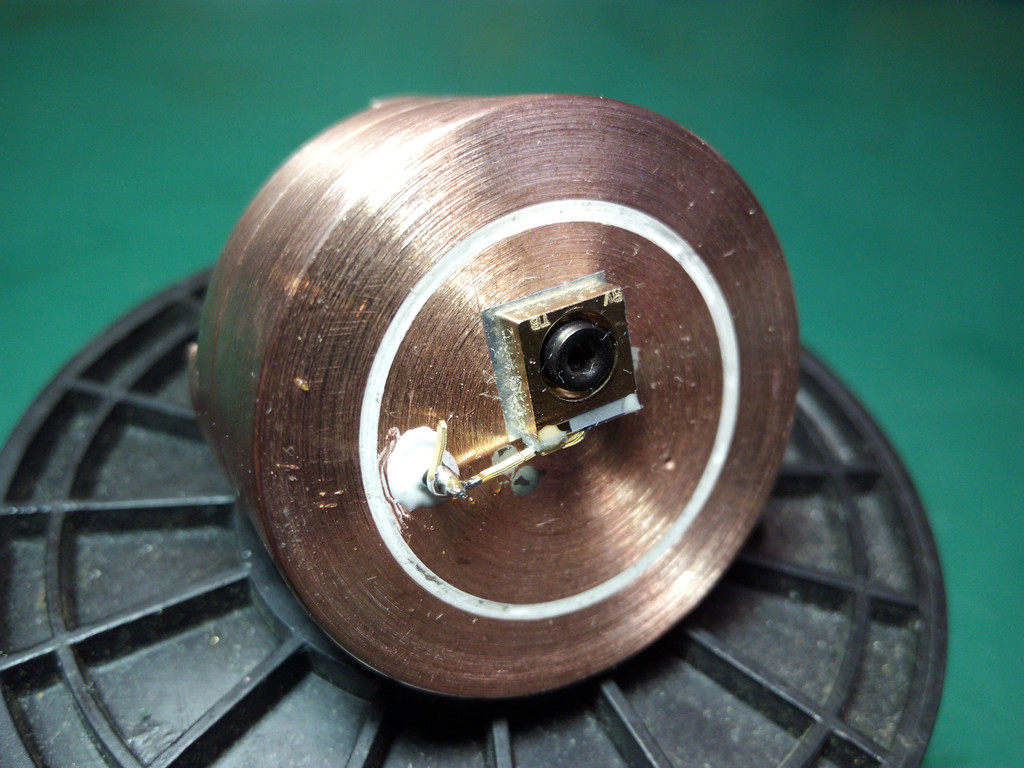

The beautiful (and very expensive) 650nm c-mount red diode:

Between the diode and the copper heatsink Angelos placed a thin indium foil to maximize the heat transfer.

Also, the central part of the copper heatsink was electrically (but not thermically) insulated from the external part by Jayrob, because the diode is case positive.

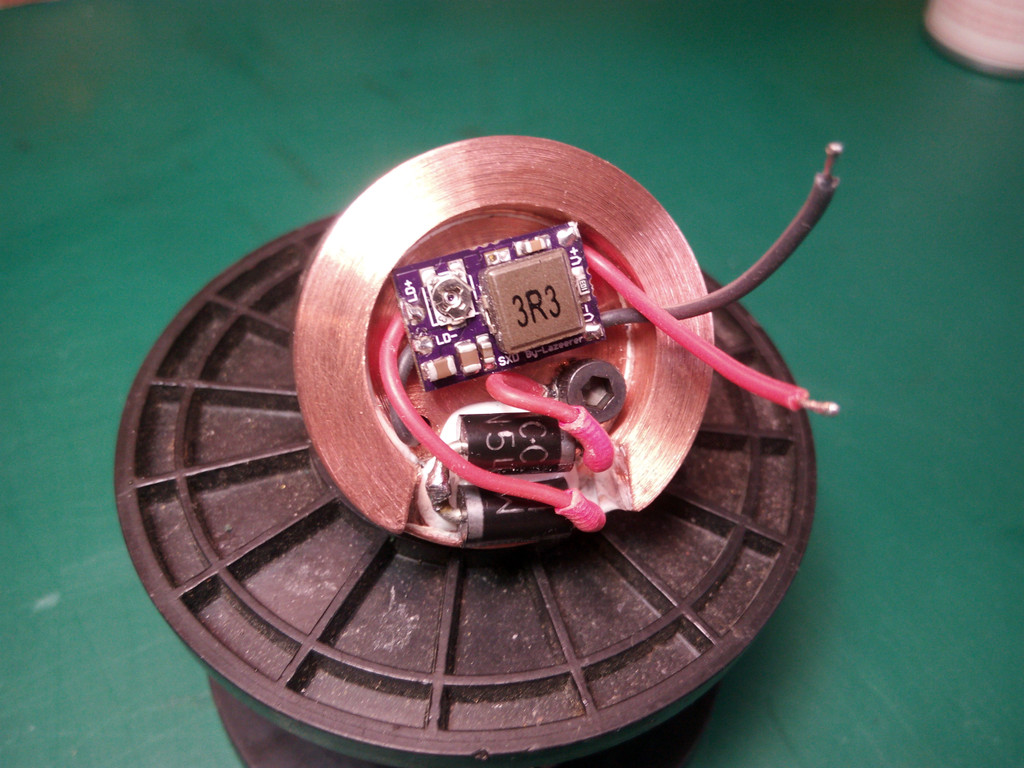

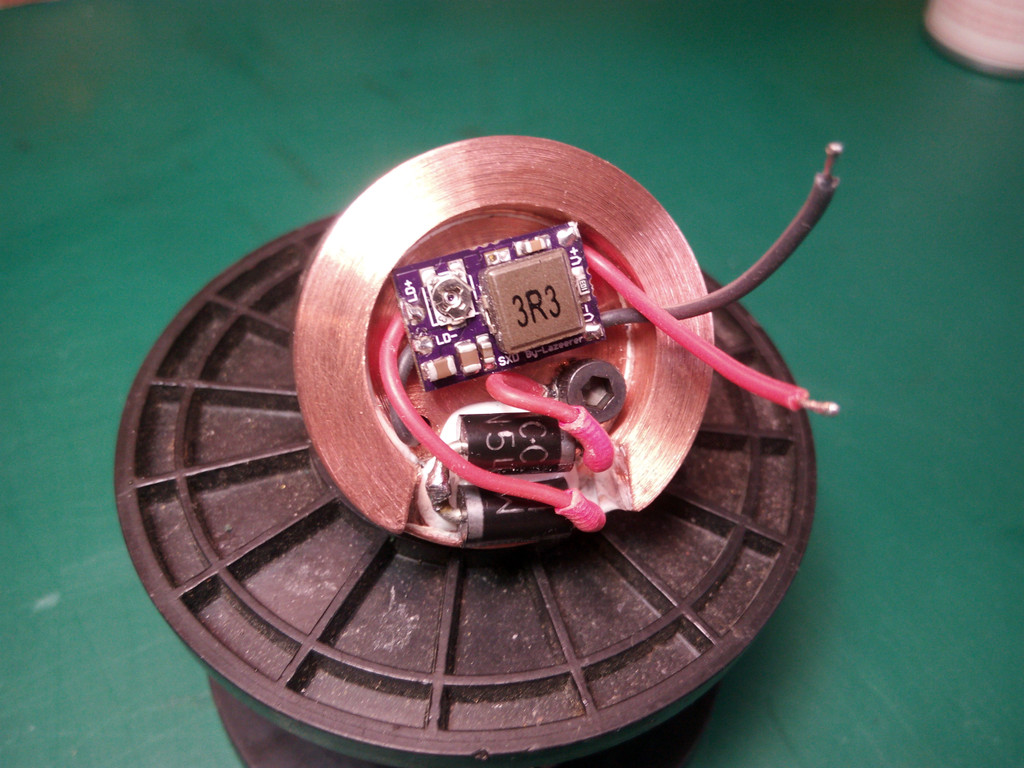

The heart of the device: the new Angelos ramp-up driver with two safety silicon diodes:

Wires soldered and insulated with thermal tubing:

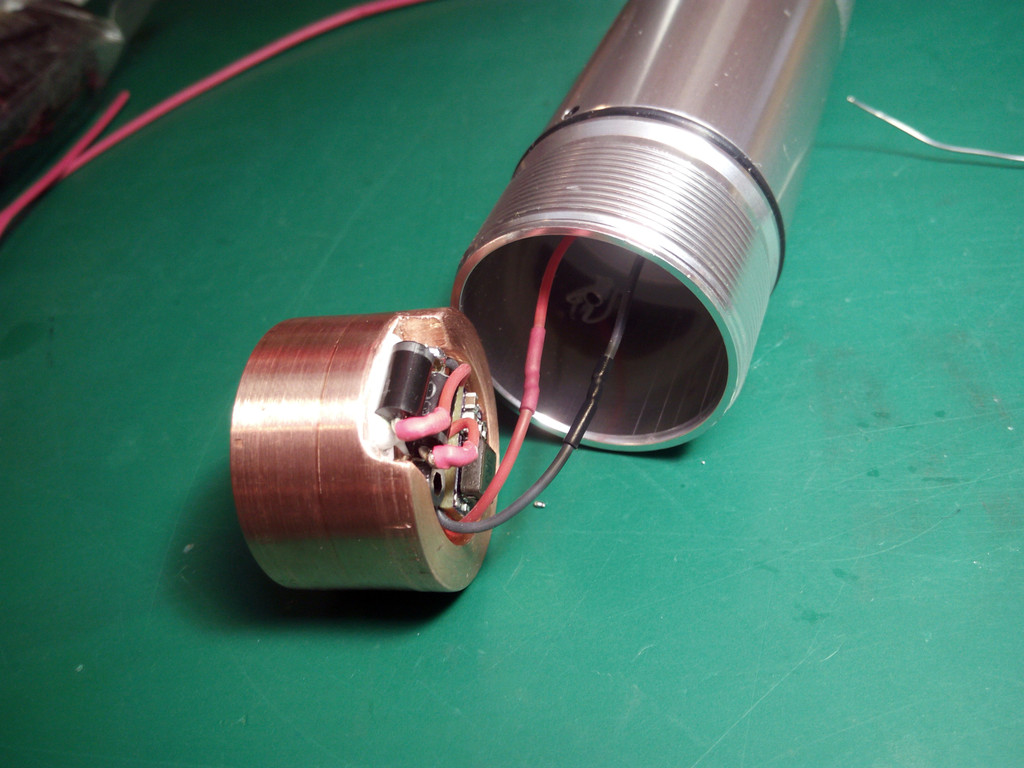

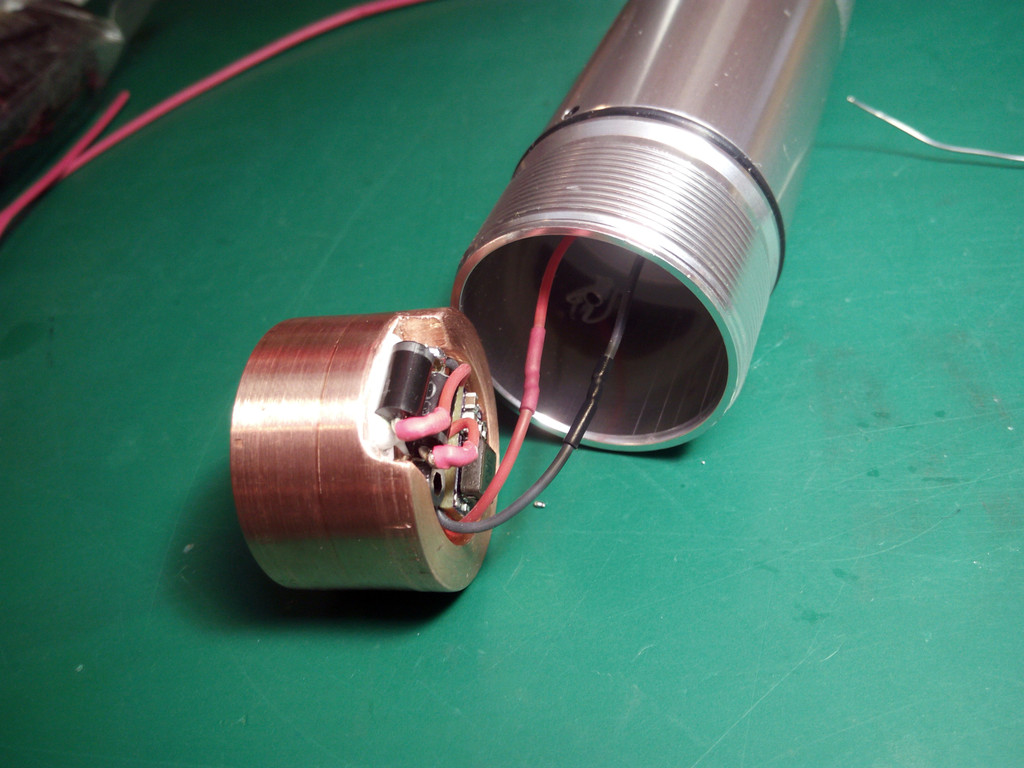

Copper heatsink inserted:

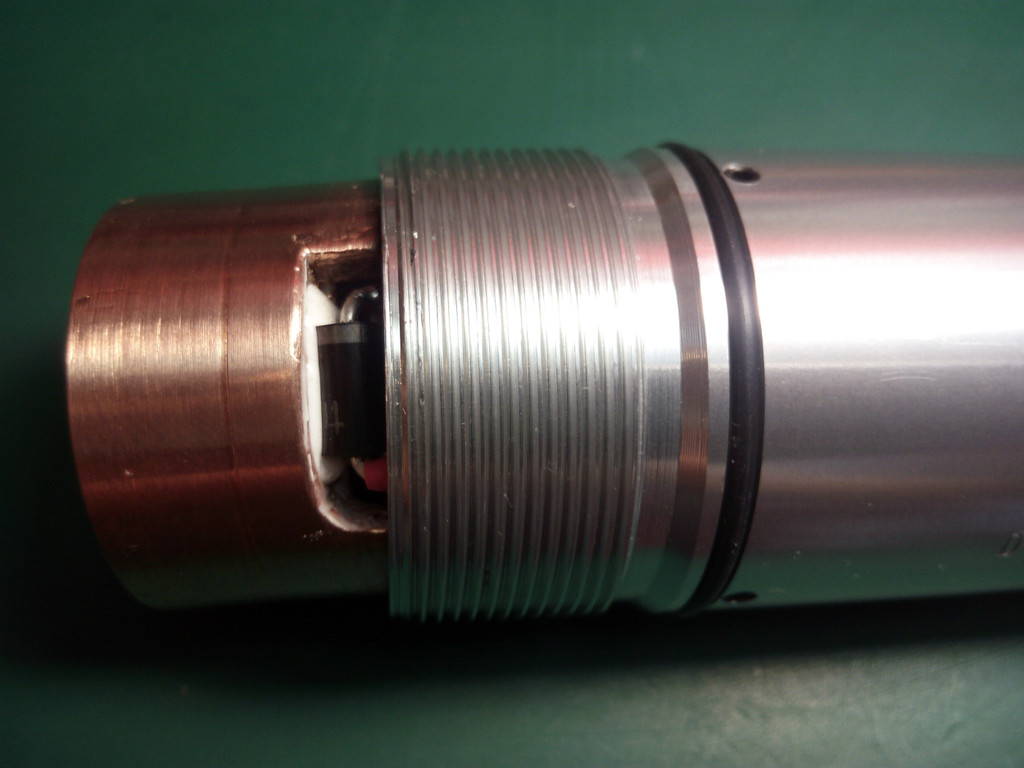

There was made three holes in the aluminum host to play with the (very little) gap of the copper heatsink, so there is the choice to centrate better the input beam inside the lens.

The beamshot inside my home (20 sec long exposure and some smoke):

(full resolution pic here: http://imageshack.com/a/img661/7269/nuThBK.jpg)

The beamshot outside (20 sec long exposure):

(full resolution pic here: http://imageshack.com/a/img673/6595/p2hmyZ.jpg)

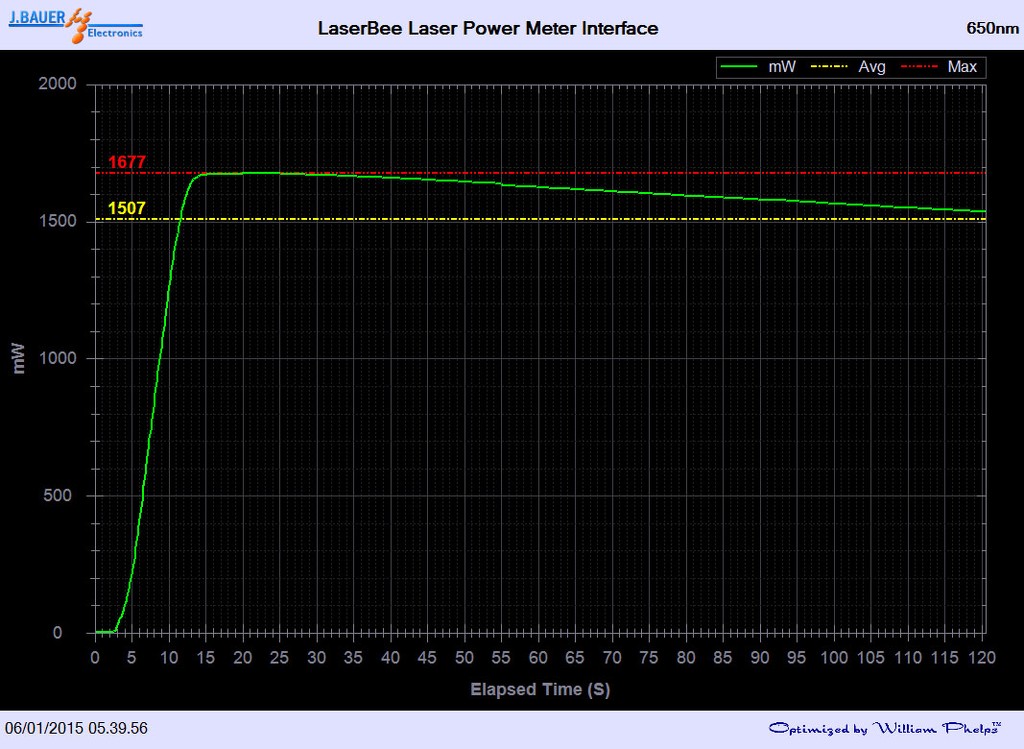

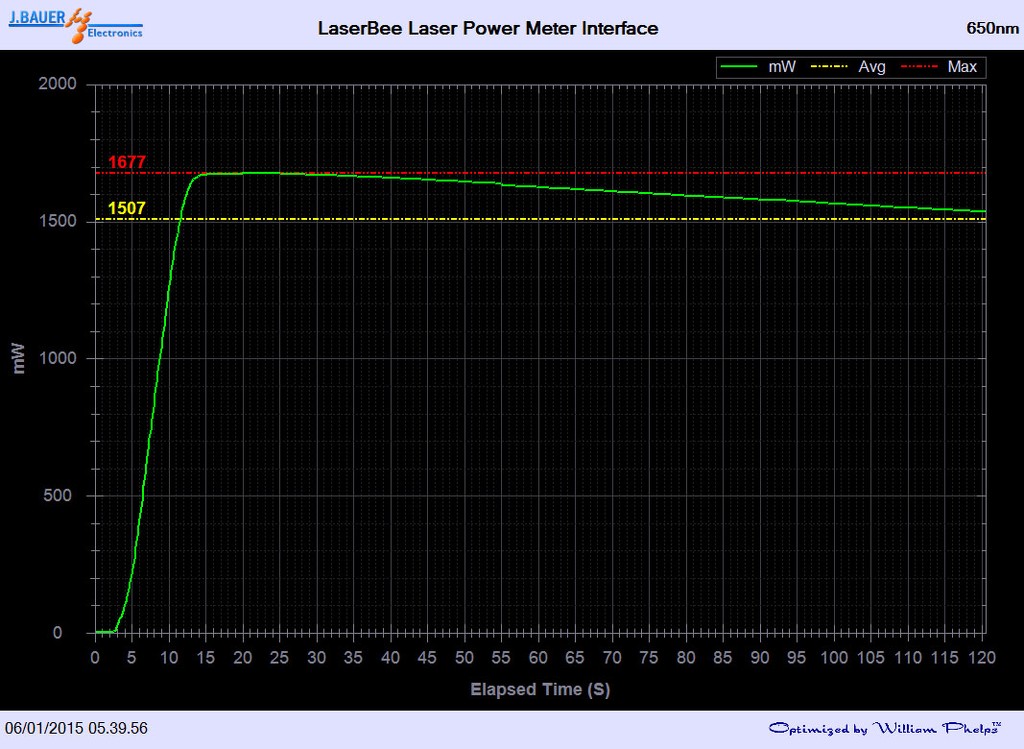

The 2 minutes performance:

There is a 17 sec ramp up, and a 170 mw power loss during the first 2 working minutes.

Angelos told me that those red c-mount diodes are very delicate, much more than other diodes, so he has limited the driver current.

The diode is already at 10°C above the max temp allowed when it is off, so the chance to kill it if I try to increase the current in high, and since in the past I already have killed an identical 350 dollars diode, it is better do not reply the tragedy again!

Also, despite the indium foil, the copper heatsink and the external big aluminum heatsink, it is better to keep short duty cycle for the above mentioned facts.

Conclusions: this laser was done only for collection. The dot shape is between a line and a rectangle, it has a long range focus, it is not so visible, it is very expensive, it is delicate. It is not a laser for everyone.

If I had a time machine, surely I do not repeat a similar odyssey. I'm happy to have this laser working, but surely it will be a laser little used.

After 18 waiting months and the same budget spent for an Hercules 600, I have finally in my hand a c-mount red laser with the new Lazereer ramp-up driver.

I prefer to avoid to list all the problems and issues that I have encountered, also because no one would ever believe a similar compilation of misfortunes.

The name "Jayzereer" was an invention of mine, in honor of the big work done by Jayrob and Lazereer.

So, the host has a massive 1085 grams weight (with cells), it uses 2x32650 6000 mAh Li-On black quality cells, it is rock solid, eye-catching and come with a generous aluminum heatsink.

The whole heatsink contain also the lens, and it is spinning, so to obtain the required focus it's enough to rotate the whole heatsink. This was a very good idea by Jayrob!

Here are some nice shots:

The host fully assembled:

(full resolution pic here: http://imageshack.com/a/img633/16/IaUGfD.jpg)

The headsink (head plus heatsink LOL):

The long-focus lens inside the head:

Inside the host:

The host and the original tailcap:

The modded tailcap:

(the modify was needed because there was too much spring pressure against the cells)

The cells:

The beautiful (and very expensive) 650nm c-mount red diode:

Between the diode and the copper heatsink Angelos placed a thin indium foil to maximize the heat transfer.

Also, the central part of the copper heatsink was electrically (but not thermically) insulated from the external part by Jayrob, because the diode is case positive.

The heart of the device: the new Angelos ramp-up driver with two safety silicon diodes:

Wires soldered and insulated with thermal tubing:

Copper heatsink inserted:

There was made three holes in the aluminum host to play with the (very little) gap of the copper heatsink, so there is the choice to centrate better the input beam inside the lens.

The beamshot inside my home (20 sec long exposure and some smoke):

(full resolution pic here: http://imageshack.com/a/img661/7269/nuThBK.jpg)

The beamshot outside (20 sec long exposure):

(full resolution pic here: http://imageshack.com/a/img673/6595/p2hmyZ.jpg)

The 2 minutes performance:

There is a 17 sec ramp up, and a 170 mw power loss during the first 2 working minutes.

Angelos told me that those red c-mount diodes are very delicate, much more than other diodes, so he has limited the driver current.

The diode is already at 10°C above the max temp allowed when it is off, so the chance to kill it if I try to increase the current in high, and since in the past I already have killed an identical 350 dollars diode, it is better do not reply the tragedy again!

Also, despite the indium foil, the copper heatsink and the external big aluminum heatsink, it is better to keep short duty cycle for the above mentioned facts.

Conclusions: this laser was done only for collection. The dot shape is between a line and a rectangle, it has a long range focus, it is not so visible, it is very expensive, it is delicate. It is not a laser for everyone.

If I had a time machine, surely I do not repeat a similar odyssey. I'm happy to have this laser working, but surely it will be a laser little used.

Last edited: