Found this here...

Does aluminum dissipate heat better than copper? - Overclockers Forums

"OK, specific heat (Cp) is the measure of how much energy it takes to raise the temperature of 1kg of material 1degree (C or K). The Cp for copper is 385 Joules/kg*K and for aluminum is 903 J/kg*K (at 300K = 23 deg. C). density for both is copper: 8933 kg/m^3 and alum: 2702 kg/m^3

So, if we have two same SIZED blocks of material, say 1m x 1m x 1m for simplicity, we have different masses, namely 2700kg of alum. and 8930 kg Cu. if we put 2.438 x 10^6 Joules of energy into each block, we can calculate the temp raise:

Q = m*Cp*deltaT --> deltT = Q/(m*Cp)

deltaT alum: = 2.4381 x 10^6 J/(2700 kg * 903 J/kg*K) =1 degree

deltaT Cu: = 2.4381 x 10^6 J /(8933 kg * 385 J/kg*K) = 0.71 degree

so for the same SIZE blocks, more heat is energy is required to heat the copper by the same delta T than the aluminum. In other words from the moment you turn your computer on it will take a longer time for a copper heatsink to reach steady state conditions.

Now since these blocks have the same size they have the same surface area (that's what we're comparing, right - same size/shape/etc... heatsinks)

Now, that is really transient heat transfer, where there is a buildup of heat in one of the components of the system (the heatsink). At steady state, BOTH Al. and Cu. heatsinks will stabilize at a certain temperature and the heat per unit time (J/s = Q_dot) will be exactly equal to the heat leaving the heatsink per unit time. It will just take a longer time for the Cu one to reach this point.

Now we're talking steady state:

2 processes going on:

(1) is conduction of heat through the heatsink

(2) is convection of heat from surface of heatsink to air

for conduction: Q_dot = (kAc/L)*(Tdie - Tsurface) <-- equation (1)here Q_dot is joules/second or Watts, k is the thermal conductivity of the material in Watts/meter*K, Ac is cross sectional area through the heatsink in meters^2, L is the lenth between Tdie and Tsurface in meters, Tdie is temperature at the die or temperature at the bottom of the heatsink (here we'll consider them equal) and Tsurface is the temp. at the surface of the heatsink, where the air contacts it. (temps in degrees C or K)

for convection: Q_dot = hA(Tsurface - Tair) <-- equation (2)

where A is the area of the surface of the heatsink (giving heat to the air) and h is the convection coefficient and has units Watts/meters^2*K.

from equation (1): Tdie = Q-dot * L/(k*Ac) + Tsurface

from equation (2): Tsurface = Q_dot/(h*A) + Tair

combining: Tdie = Q_dot*L/(k*Ac) + Q_dot/(h*A) + Tair

Taking the Tair, Across section of the heatsinks, A surface of the heatsinks, L length of the heat must travel between the die and surface, and Q_dot to be constant and the same in both cases (Ac, A, L wil be same because we are comparing the same heatsinks just of different materials, but the physical dimensions are the same, Q_dot is constant because the cpu puts out a fixed amount (ideally) say xxxWatts under load, and Tair is constant for it to be a fair comparison)

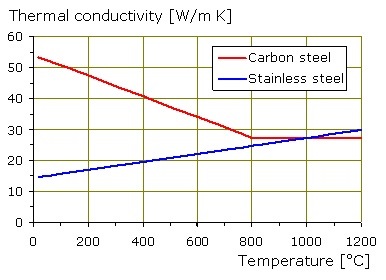

k for alum = 237 W/m^2*K

k for Cu = 401 W /m^2*K

--->You can see from the resulting equation that to make Tdie lower the only thing you can change is to make k, the thermal conductivity bigger - which is why COPPER WILL ALWAYS YIELD LOWER TEMPS FOR THE STEADY STATE HEAT TRANSFER. "