Do you personally have access to the tools and chemicals required?

(or know how to use them?)

such as a lathe, a work area to mix chemicals and apply/dry them, etc.

Doing this yourself is very cheap. I estimate my beamdump to cost less then 15$. and that is for the thermal epoxy and the aluminum. (Keep in mind I have this stuff on hand and the tools needed) If you need to buy everything off hand.. then I think you should prepare to invest far more then just 15$. Im not sure, but I belive it would vary on where you live, and what stores you are getting your supplies from.

If you cannot find from your local shops, then an idea is to look online and buy some decent quantaties.

Im sure there are stores online, but I personally bought mine locally.

Coating wise, for a simple coat like my one for testing, it didn't take much setup or effort. simply mixing the epoxy and the graphite and brushing it onto the dump.

Anodizing can also be done at home, but its a bit messy IMO.

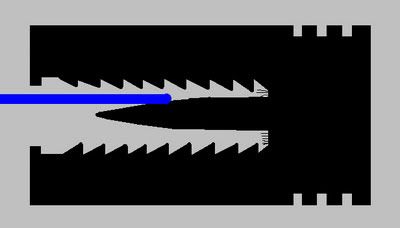

Also, for the cone/ribbing design, I was thinking something like a sawtooth pattern, with the flat ends facing towards the laser's impact point.

That way so incomming scatter around the dot itself, would be reflected sideways, while backsplash from the impact point, would just be reflected backwards into the beam dump (although some will escape through the apperture, although I dont think you can do much about that, as thats where your laser is entering in the first place.)

EDIT:

To give a better idea what im trying to say, this is how I will machine my final one next month to use as a propper beamdump.

it will look something like this:

This is not very proportional, but gives accuracy to the concept of the design. It will be coated with what I said earlier in the thread.