IgorT

0

- Joined

- Oct 24, 2007

- Messages

- 4,177

- Points

- 0

FS: >130mW PHR & 185-215mW 6x Blu-Rays, >300mW BR lasers in prototyping stage!

Jay: You are correct in requesting that, because it does make people think of your work...

Not to mention the mixup with the hosts... :yabbem:

I should have made it more clear that it was an inferior rip-off of your design. Did so now, left any names out tho....

I am sorry for the confusion and the mess.

More than a little shocked, i fell into explaining what i found upon opening it up, but didn't take enough time to check if my words could be misunderstood as to WHAT i was repairing...

After rereading them, i DID find a way to misunderstand them, so i changed the sentences completelly.

I hope all is well now...

Otherwise, Jay, what do you think of my diode window scraping attempt? :angel:

I am still in complete shock, that not a single scratch is visible!!!

I can't believe how hard these coatings are!

I modified the tool (and i won't say what it was so as not to give anyone funny ideas - if someone NEEDS to know, email me) before the scraping, by first sanding it round and then polishing it with several different finer and finer polishing tools, to minimise the resulting scratches (which i was 100% sure would appear). But they didn't!

I mean, i did it out of utter desperation. I thought that it can't get worse than it already is, even if i break the window! SOMETHING got baked onto the window - in it's direct center where the light intensity is the highest - in the few seconds of my first power-up attempt!

It got baked there so hard, that acetone could not dissolve it even when i filled the module to the top with it! Nor could other polar or non-polar solvents (and i have several, which i went through before resorting to STEEL :yabbem .

.

I still can't believe it was STEEL that finally did the trick!

Interestingly, the acetone started leaking out from under the diode way too fast, when i filled the module up, making me think it is not even inserted properly.

I'm thinking if i should use the removal tool you were kind enough to make for me (THANK YOU VERY MUCH, Jay!) to take it out, before cutting the poor copy of your sleeve (mini heatsink) shorter for a better fit....

That would also allow me to apply some thermal paste between the diode and the module before reinserting it. Something that is even more important in smaller lasers.. Altho i think i haven't made a single laser, be it "big" or tiny, where i didn't put thermal paste between the diode and the module yet.

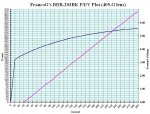

I think i should take it appart completelly, so that i can also check the actual current setting, and even plot the diode (never seen a SF-AW before).

But that's all for later.

It's evening now, and i have three special diodes to plot... Too bad i can only do destructive testing on two of them.. :angel:

Jay: You are correct in requesting that, because it does make people think of your work...

Not to mention the mixup with the hosts... :yabbem:

I should have made it more clear that it was an inferior rip-off of your design. Did so now, left any names out tho....

I am sorry for the confusion and the mess.

More than a little shocked, i fell into explaining what i found upon opening it up, but didn't take enough time to check if my words could be misunderstood as to WHAT i was repairing...

After rereading them, i DID find a way to misunderstand them, so i changed the sentences completelly.

I hope all is well now...

Otherwise, Jay, what do you think of my diode window scraping attempt? :angel:

I am still in complete shock, that not a single scratch is visible!!!

I can't believe how hard these coatings are!

I modified the tool (and i won't say what it was so as not to give anyone funny ideas - if someone NEEDS to know, email me) before the scraping, by first sanding it round and then polishing it with several different finer and finer polishing tools, to minimise the resulting scratches (which i was 100% sure would appear). But they didn't!

I mean, i did it out of utter desperation. I thought that it can't get worse than it already is, even if i break the window! SOMETHING got baked onto the window - in it's direct center where the light intensity is the highest - in the few seconds of my first power-up attempt!

It got baked there so hard, that acetone could not dissolve it even when i filled the module to the top with it! Nor could other polar or non-polar solvents (and i have several, which i went through before resorting to STEEL :yabbem

I still can't believe it was STEEL that finally did the trick!

Interestingly, the acetone started leaking out from under the diode way too fast, when i filled the module up, making me think it is not even inserted properly.

I'm thinking if i should use the removal tool you were kind enough to make for me (THANK YOU VERY MUCH, Jay!) to take it out, before cutting the poor copy of your sleeve (mini heatsink) shorter for a better fit....

That would also allow me to apply some thermal paste between the diode and the module before reinserting it. Something that is even more important in smaller lasers.. Altho i think i haven't made a single laser, be it "big" or tiny, where i didn't put thermal paste between the diode and the module yet.

I think i should take it appart completelly, so that i can also check the actual current setting, and even plot the diode (never seen a SF-AW before).

But that's all for later.

It's evening now, and i have three special diodes to plot... Too bad i can only do destructive testing on two of them.. :angel:

Last edited: