I am updating this thread with some more detailed information. Another LPF member is building a 660nm red with the same LOC LPC-815 laser diode and the rkcstr Micro-Drive. He wants specifics regarding the test load and driver adjustment. I'll add some other information useful for anyone else trying to build a red with the same laser diode and driver.

Power chart for the LPC 815 laser diode. Save this chart, print it use it at the workbench.

http://laserpointerforums.com/f50/red-laser-diode-roundup-36202.html

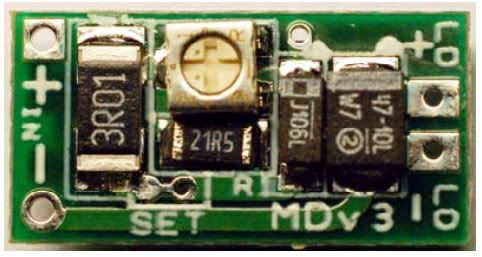

This is the rkcstr Micro-Drive. Power connects to the + & - solder pads marked IN. The test load connects to the pads marked LD + & -. After driver current is adjusted with the pot in the middle of the driver the laser diode is soldered to LD + & -. The solder pads are on both sides of the circuit board so that you can make temporary connections to the Micro-drive during adjustment by using simple test leads. Using test leads saves you from soldering the test load to the driver and desoldering it after the adjustment is done.

This is the test load for the LOC LPC-815 laser diode. It is four 1N4001 rectifier diodes connected in series with a 1 ohm resistor. The diodes and the resistor are soldered together. There is a band printed next to one end of the diode body. Make sure that the diodes are connected so that the banded ends are closest to the resistor. The banded ends are the - (negative) end of the diodes.

Usually a 1/4-watt carbon film resistor is specified for this test load. I bought these parts at Radio Shack where they didn't have any carbon film 1 ohm resistors. I bought a 10-watt wire-wound resistor instead and it works just fine.

The diode side of the test load connects to the driver at LD+ and the resistor side connects at LD-.

Here is the test load and DMM set up with test leads. Moving from left to right in the picture below: test leads ready to connect to the Micro-Drive. Red goes to LD+, Black to LD-. Test leads are properly connected across the resistor. The DMM is an entry level Radio Shack DMM.

I like to have all connections made and the DMM turned on before firing up the driver for adjustment. That way I can see the peak value at startup and watch it settle down a couple of seconds later.

The DMM is set for mV for tests with this test load. The value on the meter in volts will be equal to driver output in amps with this test load. Example: 350mV on the meter = 350mA output from the driver.

After you have completed driver adjustment and are happy with the output, turn off power, disconnect the test leads and solder the laser diode to the driver. A word of WARNING here: A current charge will remain in the driver capacitor after the driver is turned off. If you touch the laser diode to the LD + & - pads before discharging this current you will probably destroy the laser diode. To discharge the driver: short circuit the driver by touching the ends of a single wire or test lead to the LD + & - pads.

Here is another way to run adjustment tests if you have a better quality DMM that can handle the current (the Radio Shack DMM shown above can't). This slightly better old Equus DMM can handle up to 10 amps, more than enough for the current required by the LPC-815 diode. Typically, these better quality DMMs have multiple jacks for the test probes. Simply set up the DMM to an upper mA range and connect the meter directly to the LD + & -. No test load is needed.

Finally, some of the tools that came in handy for me during this DIY laser project. I don't show the test leads here or tools that I needed for working on the host and heat sink like a file, hacksaw, belt sander and drill.

The LOC LPC-815 laser diodes are not expensive and can be used by most anyone with basic tools and skills to a make a high quality DIY laser. For not much more money than you need to purchase a 200mW Chinese laser that is probably underspec you can build a better laser yourself. DIY gives you the opportunity to be creative with design and come up with a custom laser.