Re: First 660nm in progress (Done!)

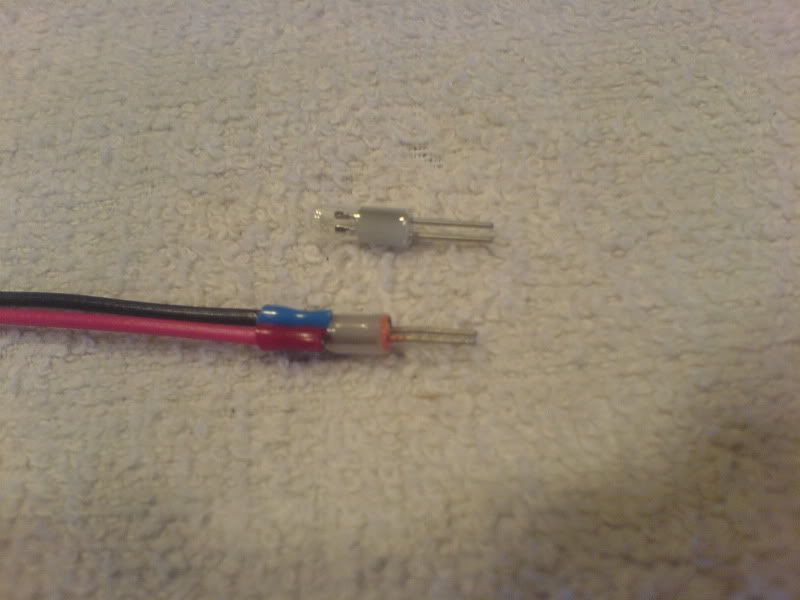

I killed the rkcstr driver two weeks ago as well as the diodes. Bad test connection. The new rkcstr arrived last week and the LPC-815s got here yesterday. I harvested one of the diodes last night and wired up the new rkcstr with a little less wire this time. I'm getting good at harvesting and mounting diodes. I cut the globe from one of the MiniMag bulbs (MiniMag comes with a spare bulb stored in the end cap) with a fine bastard file, removed the filament and used it as a plug to connect the driver to the MiniMag bulb socket and switch assembly. I marked the plug and bulb socket for polarity.

The parts used for this MiniMag build. The goal is to retain the original barrel switch and end cap. It's not easy to cram all of the needed components into a MiniMag.

Top: The MiniMag head, barrel and end cap. The only modification to these parts is to shorten the end cap. I'll explain later.

Second row from top: Three of the MiniMag parts that are not used in this project are the original thin O-ring, lens, and reflector.

Third from from top: parts in the order in which they are installed. MiniMag lens ring, fat O-ring (7/8 X 3/4 X 1/16), the washer cut from 1mm Formica with 12mm hole, bronze heat sink section, one half of the AixiZ laser module, C-clip: 10mm, second half of the AixiZ module, main bronze heat sink.

Bottom row: various electronic parts in anti-static bags including the laser diode, wire, glass AR coated lens assembly and laser driver.

The additional mechanical parts were purchased at Ace Hardware. Bronze is not a particularly good heat sink material but should work OK for this project. Copper and aluminum are much better for this purpose, but I couldn't find suitable pieces. I don't have a lathe to machine a proper heat sink so I'm making do with what I can. The bronze bearing material is .5" ID, 5/8" OD. The O-ring is from the plumbing department.

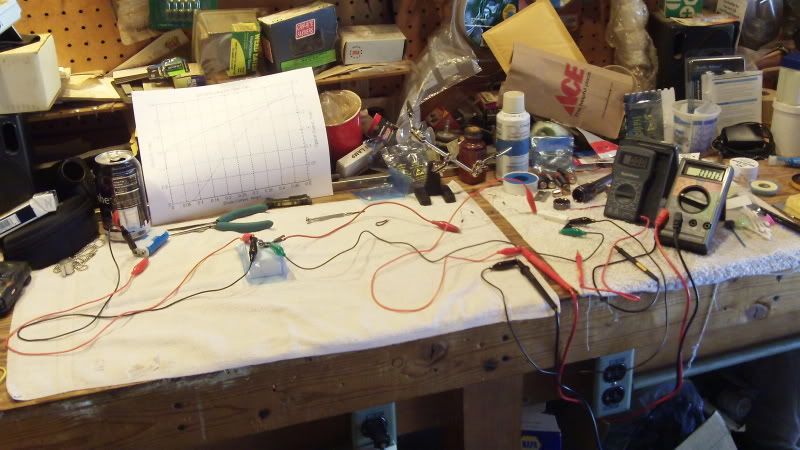

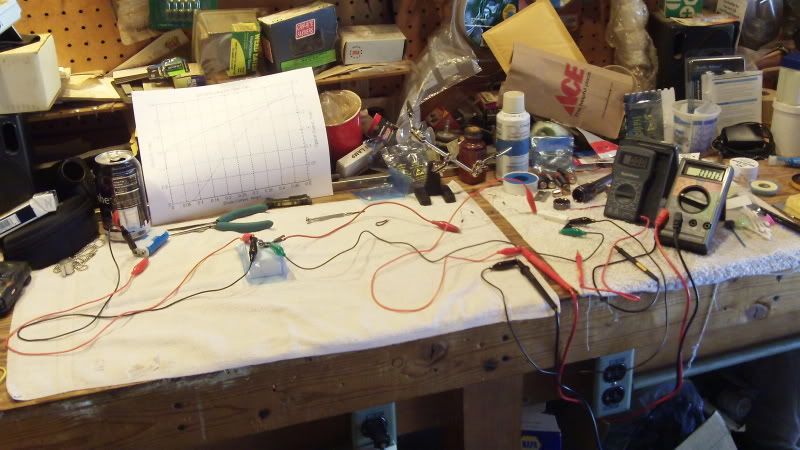

Last evening, I used nearly the same driver adjustment and test set up as two weeks ago. The test leads are not a problem: just set them up securely and carefully. The laser diode will not be used to make these tests. I'll solder that directly to the driver after tests. I adjusted driver output with a dummy load and measured voltage across the resistor, setting the driver for 360mV. I tested with both DMMs to make sure. I'm being more conservative with the output this time. After this test, I waited 30 minutes to let the driver and diode return to room temperature and repeated the test. The DMM showed 365mV initially, which settled down to 361mV ten seconds later. The old Equus DMM will handle the amps so I tested driver output again measuring current directly from the driver output (no dummy load). The test showed an initial 370mA that settled down to 360mA ten seconds later. No further adjustments being necessary, I disconnected the meters and proceeded to finish the build. Output for this 660nm will be about 220mW, maybe a little higher for the first five seconds or so. I read somewhere that using the AR coated AixiZ lens is worth another 10% in output power over the plastic lens, so maybe I can call it a 240mW laser.

All ready for final assembly. I used a hacksaw to cut a good 1.5 mm off the thread end of the end cap. I also snipped two full loops off the top of the battery spring and another one loop from the wider base of the spring. That will accommodate additional length of the two protected 14500s. The cut coil at the top of the spring will be sharp enough to scratch up the bottom of a battery, so I sanded it down and used some stout long nose pliers to bend the cut end toward the center of the spring.

The assembled MiniMag 660nm. She has a big nose, but I think she's beautiful. Yes, you turn it on by holding the hood with one hand and twisting the barrel slightly. It's a nice, silky feeling and positive acting switch. The AR coated glass lens protrudes from the AixiZ module farther than the plastic lens.

More cell phone shots. Shooting 25' across a hazy garage and hitting the far wall.

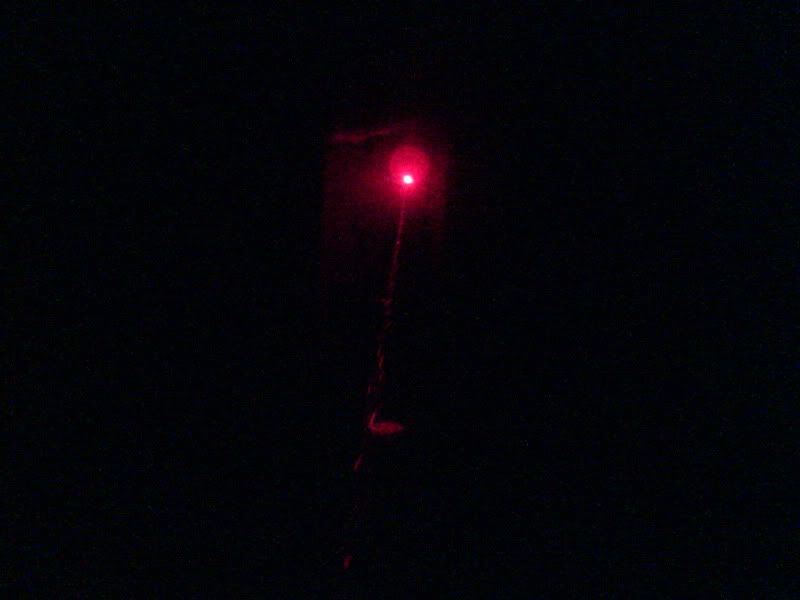

Now, this is what amazes me. I took the laser out to the backyard at 11:30 p.m. and aimed for some tall trees. I could see the red beam! It was faint, but there. I didn't expect to see any red beam in clear air. I took this shot showing some of the beam and the spot hitting the wall of my house 50' away. I could see this beam much better than the cell phone cam could.

I'm a happy camper.:yh: