About the calibration, i have a different suggestion.

The method that you have posted, is a good system when you already know the reflection/absorption index of the TEC plate and paint layer, but can give some imprecision, if used with unknown TECs systems ..... i mean, anyone can have a different TEC, with different surfaces (bare ceramic, gold plated, indium tinned), and can use the paint that they find in their stores, and you probably know that these paints have a lot of different reflection/absorption coefficents .....

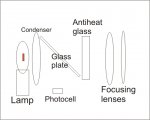

I'm trying to build something reproducible, using a specific filament lamp and lenses that can be found easily (still works in progress, sorry) ..... anyway, the principle is the following one: if i get a lamp type that can be found almost all around the world (as example, car lamps, that are more or less standardized both in production and distribution), and focus the filament image on a certain dimension on the reading plate, with a precise voltage, i can build, probably, a decent thermal calibration system that is independent from the plates and paint layers .....

So, regardless, if one have a 5mm TEC with acrylic black, or a 8mm TEC with exhaust tubes paint, or anything other, you can calibrate it for the right value, cause the assembly send always the same power to the reading face .....

Actually i discarded the "signal" lamps (too much incostants), and i'm experimenting with H1 lamps, and H4 lamps using the shielded filament, and had some decent result as "constant emission vs power supply" from osram and philips lamps, and horrific

results using the "chinese" or streetmarket cheap ones ..... who know what brand is the more diffused one, or if there's any other more "stable" ? (only standard lamps, not the "blue glass" or strange others, need that the lamp can be found a bit everywhere with the same characteristics)