- Joined

- Sep 16, 2007

- Messages

- 3,667

- Points

- 113

I've done some lens shaping with a fine diamond file and water. It's a tedious process but it does work. Just be sure to mask the optical surfaces you want to keep... optical.

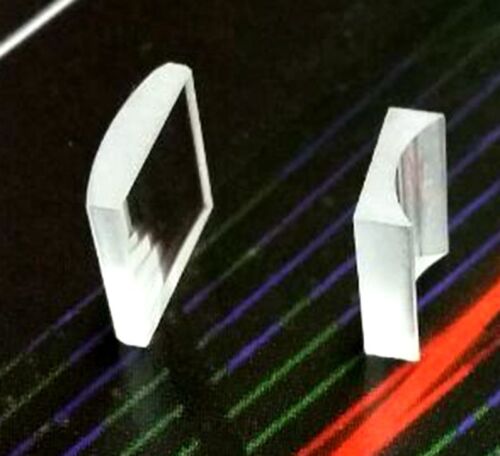

I've made round lenses rectangular and even reduced the diameter of a wedge prism so it would fit one of my projects.

Just pay attention and be careful.

I'd probably go for a very small diamond coated needle file for splitting a cylindrical lens. Power tools run the risk of grabbing the lens and launching it into orbit.

Maybe practice or experiment on a similar but less valuable item first.

I've made round lenses rectangular and even reduced the diameter of a wedge prism so it would fit one of my projects.

Just pay attention and be careful.

I'd probably go for a very small diamond coated needle file for splitting a cylindrical lens. Power tools run the risk of grabbing the lens and launching it into orbit.

Maybe practice or experiment on a similar but less valuable item first.