- Joined

- Mar 5, 2015

- Messages

- 1,333

- Points

- 113

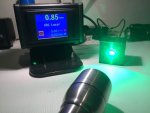

So in my search for laser hosts I came across the Coast hp14 at my local Cash converters, it was second hand and a little banged up, but a very nice solid torch, so for $45 I knew it would be an interesting laser build.

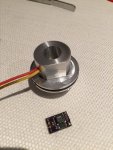

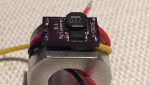

I have always preferred smaller builds however it would be nice to own a large good quality laser. I was very happy to find out that Budgetbeams XML T6 heatsink fits this host perfect, the 12mm hole was just a tad loose for Jordan's copper module so instead of using thermal adhesive and never being able to remove the module again, I spread some thermal adhesive evenly all around the inside about a millimetre thick let it dry then gently using a round file on my handy drill press I filed it down for a perfect press fit and also added some thermal grease, now the set screw isn't necessary but I tightened it up anyway.

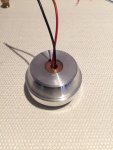

I decided to modify the host to a smooth aluminium look, in the process removed all the dings piece by piece until I was happy with the finish, I should have polished it up also, maybe later.

I've added plenty pics to detail the build process for anyone interested.

I haven't had time to modify the battery compartment just yet, But the original module for the batts holds 4 14500 so 16.8v might be fine if not 3 with a spacer will do well.

The clicky on this host is exceptional very solidly constructed. Thanks again to Jordan for the NDG 700 and the Xdrive 1.8a driver and the 3 day express shipping to Australia.

I have always preferred smaller builds however it would be nice to own a large good quality laser. I was very happy to find out that Budgetbeams XML T6 heatsink fits this host perfect, the 12mm hole was just a tad loose for Jordan's copper module so instead of using thermal adhesive and never being able to remove the module again, I spread some thermal adhesive evenly all around the inside about a millimetre thick let it dry then gently using a round file on my handy drill press I filed it down for a perfect press fit and also added some thermal grease, now the set screw isn't necessary but I tightened it up anyway.

I decided to modify the host to a smooth aluminium look, in the process removed all the dings piece by piece until I was happy with the finish, I should have polished it up also, maybe later.

I've added plenty pics to detail the build process for anyone interested.

I haven't had time to modify the battery compartment just yet, But the original module for the batts holds 4 14500 so 16.8v might be fine if not 3 with a spacer will do well.

The clicky on this host is exceptional very solidly constructed. Thanks again to Jordan for the NDG 700 and the Xdrive 1.8a driver and the 3 day express shipping to Australia.

Attachments

-

1457132348.491.iPicit.jpg310.9 KB · Views: 51

1457132348.491.iPicit.jpg310.9 KB · Views: 51 -

1457132417.5066.iPicit.jpg322.3 KB · Views: 42

1457132417.5066.iPicit.jpg322.3 KB · Views: 42 -

1457132556.1629.iPicit.jpg292.2 KB · Views: 40

1457132556.1629.iPicit.jpg292.2 KB · Views: 40 -

1457132779.6316.iPicit.jpg268.6 KB · Views: 53

1457132779.6316.iPicit.jpg268.6 KB · Views: 53 -

1457132837.4129.iPicit.jpg272 KB · Views: 42

1457132837.4129.iPicit.jpg272 KB · Views: 42 -

1457132902.741.iPicit.jpg256 KB · Views: 47

1457132902.741.iPicit.jpg256 KB · Views: 47 -

1457132989.116.iPicit.jpg283.1 KB · Views: 38

1457132989.116.iPicit.jpg283.1 KB · Views: 38 -

1457133053.0066.iPicit.jpg277 KB · Views: 40

1457133053.0066.iPicit.jpg277 KB · Views: 40

Last edited: