- Joined

- Jun 22, 2016

- Messages

- 2,686

- Points

- 113

It will take a while.

I am in the middle of a move.

So i don't have much free time.

However i do have News:

I am in the middle of programming the PWM stuff for dimming.

The uC will generate a high frequency PWM that gets smoothed to a variable analog voltage that feeds the laserdrivers.

This will give me a constant power laser output.

However i like the idea of generating rainbow lines with this pointer.

For example: One mode of the pointer will be a rainbow mode.

This will be completely different than the Sanwu pointer "colorchange mode"

This mode will adjust the brightness of each laser color very rapidly. This will give the illusion of a white beam that does not change color.

However if the pointer gets moved it will draw a rainbow colored line.

This stuff needs high speed programming and electronics.

The good news: It already works a little.

I did already implement the menu system and the PWM output.

BUT the menu systems still needs work. Right know its to complicated.

If someone is interested:

I do have 20 driver PCBs, so i could sell one or two.

Software is still pre-alpha but this will change.

Don't hesitate to write a PM.

TODO:

- Programming new menus system

- Optimizing speed of pwm generation

- Optimizing battery percentage readout (the ADC values are all over the place, maybe a programming/electrical problem)

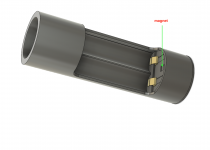

- completing CAD design of the back housing

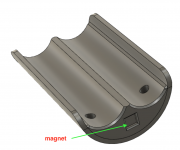

- completing CAD design of the battery holder

- CAD design of the back cap with key switch

I will post if i get something done!

have a nice day

If you need any CAD assistance / design help, I will gladly help!

Btw.. Witch processor you will use? I have full load of different PWM color modes / cycles for PIC processors written in assembly some where at my computer..