- Joined

- Sep 20, 2013

- Messages

- 20,284

- Points

- 113

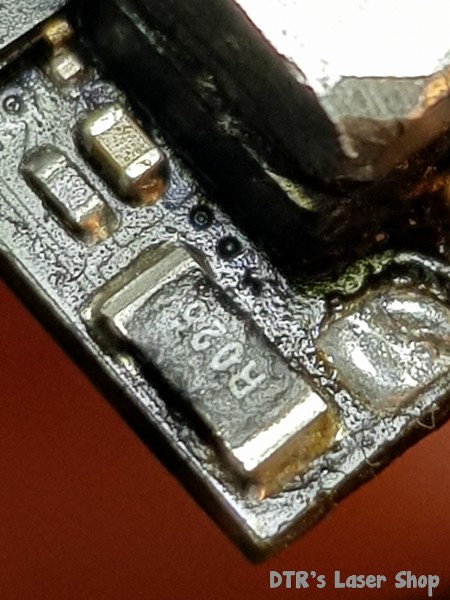

I've been using Arctic Alumina for many yeas and if you are going to keep it for long periods on time, it is suggested that you refrigerate it. I never do, however. It sets up in about an hour. It holds as strong as any thermal glue I have used that is far cheaper, but it dries harder than the silicone stuff and has better thermal conductivity too. It will end up costing you $16.00 for 5 grams total, but IMO it is worth it. Just keep it in a dark cool place when not in use and don't expect it to last longer than a few months without refrigeration. It is nonconductive.

The silicone stuff has the same thermal conductivity that silicone grease has. The arctic alumina is higher, but I can't find specs for it now. I used it on my driver from my 574nm laser and it is amazing how well it conducts heat to the sink. Just as if it were arctic silver grease with a screw holding it to the heat sink.

The silicone stuff has the same thermal conductivity that silicone grease has. The arctic alumina is higher, but I can't find specs for it now. I used it on my driver from my 574nm laser and it is amazing how well it conducts heat to the sink. Just as if it were arctic silver grease with a screw holding it to the heat sink.

Last edited: